MLZ ist eine Kooperation aus:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ ist Mitglied in:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ in den sozialen Medien:

MLZ

Lichtenbergstr.1

85748 Garching

Newsletter II/2021

Jump directly to the chapters! (and don't forget to enlarge the pictures by clicking them!)

» Editorial» Instruments» Working on projects» People» UsersEditorial

The thermal intermezzo

After quite a long absence of neutrons at the MLZ due to the Corona pandemic, we unfortunately faced a technical issue with the cold source of the FRM II in spring this year. Careful analysis of the situation yielded that the cold source had to be removed and will be replaced after a transition period of “thermal operation”.

This particularly affects all instruments in the Neutron Guide Hall West. Detailed simulations of the neutron flux at the instruments anticipated in the thermal scenario show that a user programme for the “cold instruments” starting in March 2022 will be possible. Updated information on the specific instruments is provided at our MLZ home page, and you are welcome to discuss with our scientists at the MLZ User Meeting next week.

We are very much looking forward to welcoming our users again soon! In order to mitigate possible effects of the pandemic on travel plans we are well prepared for the many facets of remote collaboration before, during and after your experiments, which gives all of us an optimistic perspective for the next year!

Instruments

» Running without cold source» At a glance

» New software at MARIA

» KWS-3: More flexible for users

» Let's quench!

» From an instrument's point of view

» TEM: Changing places

» How to move a ton of steel

Running without cold source

In August, after a long period of uncertainty regarding the status of the cold source, a clarification was achieved thanks to a concerted action by both the reactor and the science division at MLZ. After having ascertained that the cold box sitting outside the reactor pool is running well, the malfunction of the cold source could be identified in the in-pile part. A combination of MCNPX simulations, results from measurements at the instruments together with the technical and physical know-how of the cold source team unambiguously showed that the displacer inside the cryogenic vessel is not working properly. Unfortunately, as a consequence, the cold source has to be replaced. While preparations for the new in-pile part are underway, we are planning to remove the cold source at the end of 2021. Reactor operation – with termal neutrons only – is expected to be resumed in 2022, the first user cycle is scheduled to start March 01st, 2022.

Most of the instruments focussed on cold neutrons are located in the Neutron Guide Hall West. © W. Schürmann / TUM

The removal of the cold source is of course irrelevant for all instruments on thermal and hot beam tubes. The same applies to the positron beamline NEPOMUC as well as MEDAPP&NECTAR and FanGas. In contrast, the cold instruments will face a significant drop of cold flux: above a wavelength of 2 Å, the flux drops quickly to around 10% at 4 Å. Consequently, the implications for the instruments will strongly depend on their used wavelength range and the individual experiments. All instruments will remain in user operation and we encourage you to contact the respective instrument scientists to get further information on the experimental possibilities.

Additionally, measures are being taken at many of the affected instruments to compensate for the losses, but it should be kept in mind that most instruments are optimised for their wavelength range and this can hardly be changed. Nevertheless, to name just a few examples, at PANDA more measurements can be made in the thermal range, in addition the commissioning of BAMBUS (multi-analyzer bank) is being greatly accelerated and the use of artificial intelligence (AI) to optimise the measurement strategy is also being tested. At KWS-1 and MARIA, an exchange of the selectors from 10% wavelength resolution to 20% is planned or being tested, which corresponds to a doubling of the flux, and at SPHERES the ‘inelastic fixed window’ scan mode will be implemented. DNS, BIODIFF and TOFTOF routinely use wavelength below and KWS-2 around 3 Å, so their experiments can be conducted with only minor limitations. ANTARES will be used in thermal mode, and MIRA and NREX are looking into possibilities extend to smaller wavelength.

In order to optimise these measures during operation with neutrons, the first 30 days of the first cycle in 2022 will be reserved for test and instrument-specific proposals, respectively. We will report on the success of the measures on the cold instruments, whether improved or not and provide constant updates on the instrument web pages. Hopefully, these will become a source of inspiration for our users for future projects on our cold instruments!

W. Lohstroh (FRM II); S. Mattauch (JCNS)

At a glance

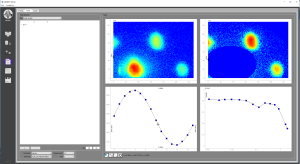

New software at MARIA

Analysis of specular X-ray and neutron reflectivity data is traditionally performed using model-based refinements. When the system under can be approximated by a succession of a few uniform layers, the use of programs that provide spreadsheet-like input of layer data, provides a convenient way for fitting experimental results. However, when an interfacial model needs to incorporate analytical expressions and constraints, such an approach tends to be restrictive.

At MARIA, we have recently introduced a new Python software package under the name anaklasis [1], where we combine an intuitive hierarchical list-based type of input with the flexibility typically found in script-based software. The package [2] offers a more natural framework for model definition requiring minimum coding literacy, and additionally advanced statistical analysis methods like Markov chain Monte Carlo sampling, thus permitting the objective estimation of parameter uncertainty and covariance.

A. Koutsiompas (JCNS)

[1] Koutsioubas, A. (2021). J. Appl. Cryst. 54

[2] https://github.com/alexandros-koutsioumpas/anaklasis

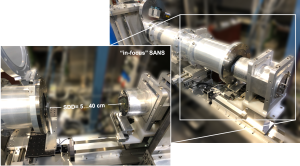

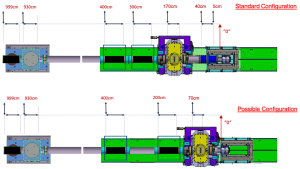

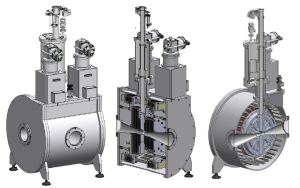

KWS-3: More flexible for users

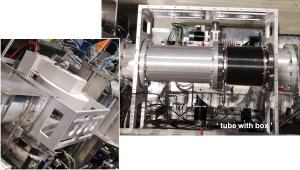

'Tube with box’. Right: if not used, the space inside the box is filled by tubes. Left: with installed 2T electromagnet. © MLZ

In 2021, we have finished several projects at KWS-3 in the direction of the instrument flexibility.

First of all, an integrated second ‘tube with box’ at the sample-to-detector distance SDD = 4 m. Now we can install a bulky sample environment at SDD=10, 4, 3, and 2 m and cover a q-range between 3.5·10-5 and 1.5·10-2 Å-1 with both sample environment, compact as well as bulky.

We can also offer a “SANS” configuration with SDD between 5 and 40 cm where we cover the Q-range of a classical SANS instrument between 2.5·10-3 and 3.5·10-1 Å-1. For strongly scattering samples like powders, we can thus perform scattering experiments with a wave vector transfer resolution between 3.5·10-5 and 3.5·10-1 Å-1, covering four decay of the dynamical range.

The second vacuum chamber was moved from SDD = 1.3 to 1.65 m in order to achieve a better overlap with data measured at the main sample position at SDD = 9.3m.

Finally, we installed a new positioning system with absolute encoders of the detector and the second sample chamber. This realizes the ‘Multi-sample-position-approach’ at KWS-3.

V. Pipich (JCNS)

Let's quench!

A Quenching & Deformation Dilatometer (TA instruments DIL 805A/D/T) is operational at the MLZ for performing in-situ neutron diffraction (phase, texture, stress/strain) at STRESS-SPEC and small-angle neutron scattering (nanostructure) at SANS-1. Imaging applications are under preparation at ANTARES. With this setup, the evolution of sample length during heating or quenching can be accurately monitored while scattering data are being acquired. Thanks to induction heating and gas cooling very high rates are accessible. Forces up to 20 and 8 kN can be applied in compression and tension, respectively. Besides, special sample holders for powders will soon extend the range of applications.

The combination of the neutron scattering and dilatometry measurements yields a unique view on the microstructural evolution under thermomechanical treatment. Further information can be found in Li X. et. al. Adv. Eng. Mater. 2021, 2100163, https://doi.org/10.1002/adem.202100163.

C. Solis (Hereon)From an instrument's point of view

Neutrons may not have been spinning and turning, but a lot has been happening on my dancefloor anyways…

My name is RESEDA and I am sure you have all been wondering what we have been up to this last, rather neutron-free year. You might think we have been lazy, but you would be VERY wrong. My humans (Johanna, Christian, Philipp, Jon, Lukas, Korbi) have been rather busy upgrading some of my systems!

You might remember that it wasn’t quite easy to insert and align your sample when coming to measure with me, guess what? We fixed that! We installed a brand new sample table with everything you might wish for! It has x-, y- & z-translation, x- & y-cradles and z-rotation AND it is strong enough to carry the 12T magnet! You want to do MIEZE at 12T? Well now you can!

We have also extended the sample-changing platform, to make it easier to change samples.

The humans have also been quite busy working on the MIASANS project. I am gonna get new SUPERCONDUCTING coils, a better detector and a pretty big vacuum tank, with this we can work even better at small Q (we may or may not have learned a thing or two from our neighbour SANS-1).

The coils are waiting to be installed (they came all the way from New Zealand), the detector is being worked on as we speak and the detector tank is being designed.

TEM: Changing places

After nine years of service in the old UYM building of the MLZ, the Transmission Electron Microscope (TEM) facility moved to the new UYL building in August 2021. This was a challenging story involving several people including JCNS and JEOL company. Two rooms (instead of only one in the old building) were waiting for the TEM instrument and the specimen preparation devices. As the microscope has been planned to be located in a larger room at the ground floor, one expects better conditions for imaging and measurements.

The gallery shows the whole story! (Just click on the first picture and navigate with the arrows on the upper right.)

M.-S. Appavou (JCNS)

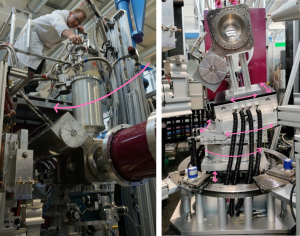

How to move a ton of steel

The MBE (Molecular Beam Epitaxy) setup is a well established user instrument which delivers thin film samples for neutron reflectometry. Since the first rumour about a new laboratory building in 2011, I was often asked if the relocation would not be too intricate. My answer was always that it will be worth it because of the gain of a much larger lab.

In September 2021 the relocation finally took place. For that two technicians from DCA Instruments, the manufacturer, disassembled the setup in the old lab and reassembled it afterwards in the new lab UYL 3.28. About 600 screws and 25 flanges had to be opened and closed with plastic caps to minimize any contamination with particles from the air – you can see them on the picture.

The distance between the labs was covered on foot with the help of our local technicians. The dry and sunny weather facilitated everything as no special covers were necessary. By the end of only one week, the instrument was under ultra high vacuum again and ready for a restart. I like to use the opportunity to thank all who supported the MBE relocation!

What are the next steps? Atomic absorption spectroscopy as a method for high quality rate calibration during growth and a new chamber with option of depth profiling analysis via ion beam sputtering and Auger electron spectroscopy will be installed.

S. Pütter (JCNS)

Working on projects

» High pressure related activities on HEiDi» ERuM Pro Project NHSM

» From Berlin to Bavaria

» On delivery

» Nested mirrors at MIRA

» Research with positrons

» NeutroSense improves detection

» New laser furnace at STRESS-SPEC

High pressure related activities on HEiDi

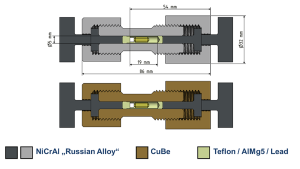

Despite the very limited availability of the MLZ in 2021, we achieved significant progress in our various HEiDi related projects. Particularly noteworthy is the BMBF project (05K19PA2) Development and Optimization of High Pressure Sample Environment for Polarized and Unpolarized Neutron Diffraction and Spectroscopy at the Instruments HEiDi, POLI, MIRA and DNS at the MLZ.

We tested newly developed clamp cells made of CuBe and NiCrAl respectively (A. Eich, A. Grzechnik, M. Poli, see fig.) successfully on HEiDi in its standard cryostat as proof of concept concerning multiparametric (P/T) studies up to the GPa range. The minimum sample temperature within both clamp cells was 4.0 K, that is only about 1.5 K above the base temperature without heavy load.

NiCrAl based cells reach potentially higher pressures but suffer from an about 23% lower transmission. Thus, we currently focus on fretted cells (see fig.) combining two sleeves of different alloys in order to achieve either max. pressure or transmission.

M. Meven (RWTH Aachen)

ERuM Pro Project NHSM

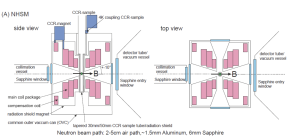

Schematic cross-section of the NHSM coil layout. The integrated CCR type cryostat shares the insulation vacuum with the dewar cooling the superconducting magnet. © MLZ

The goal of the ERuM Pro Project Next generation Horizontal SANS Magnet (NHSM) was the development of a high performance compensated asymmetric horizontal magnet optimized for SANS, reflectometry and the resonance spin-echo technique MIEZE. This magnet is dedicated for research on quantum phenomena in nanostructures, strongly correlated electron systems and superconductivity using polarized neutrons and polarization analysis. For this purpose, two project studies have been performed.

Different views /cuts of the NHSM coil and dewar layout. (Feasibility study of HTS-110, NZ) © HTS-110

NHSM will achieve a magnetic field of 9.4 T with stray fields down to 10 G at 1 m distance. It is optimized for lowest possible background scattering with the least amount of material in the beam. NHSM will be based on modern high-temperature superconducting (HTS) technology that allows the fringe field compensation of NHSM at reasonable weight (~750 kg) and size (~75 cm x 75 cm). NHSM will be a pioneering project using HTS technology without cryogenic liquids. As such, NHSM can be the prototype for future high performance magnets at neutron scattering facilities.

S. Mühlbauer (FRM II)

From Berlin to Bavaria

Instrument engineer M. Grujovic during the disassembly of FIREPOD's monochromator drum at the HZB. © D. Clemens, HZB

The BMBF funded transfer of the three axes spectrometer LaDiff and the powder diffractometer FIREPOD from the HZB in Berlin to the MLZ in Garching has entered into the next phase.

During August and September, MLZ-scientists and engineers joined the HZB-team to carefully disassemble both state-of-the-art instruments at their previous locations at the former neutron source BER2.

Taking part in deconstruction gave the new instrument responsibles an exclusive chance to retain valuable knowledge about the detailed layout and the unique capabilities of both instruments, which is vital for the upcoming transfer of both instruments and their further usage.

The delicate components are now awaiting final approval for packaging and shipping, currently planned for January 2022. After their safe arrival on site, the next big step is a swift integration of LaDiff and FIREPOD into the existing MLZ infrastructure.

C. Hauf (TUM)

On delivery

“Wow, that is absolutely massive!” All involved persons knew by heart that the delivery would be 12 m long. But there is a difference between knowing and seeing it finally in place….

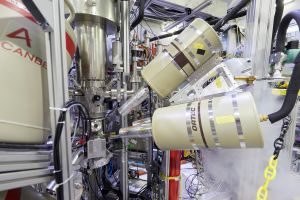

The DFG funded PERC (Proton Electron Radiation Channel) is set up at the beam site of MEPHISTO in the Neutron Guide Hall East and will aim for measurements of neutron beta decay. Those provide information about the Standard Model and thus permit sensitive searches for new physics. While the accuracy level is limited to 10-3 at the moment, PERC will increase this by one order of magnitude.

Its main component ist a superconduction magnet system. And this 12 m long 13 t monster was delivered to Garching on a sunny September day. The User Office, located above the Neutron Guide Hall East, used its box seats for taking many photos – enjoy the gallery!

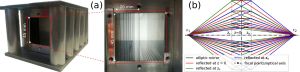

Nested mirrors at MIRA

a) Prototype of a nested mirror geometry and b) its cross section highlighting the neutron paths determining the spacing of the mirrors. © MLZ

“You can break every law except the laws of physics”. Passing as a joke among undergraduates, the quote catches up with us when finally working as a scientist. While it is indubitably a bad idea to violate any of the many German laws, especially at a reactor source, physical constraints can be equally headache-provoking to deal with.

Among the latter, Liouville’s theorem governs the interplay of a neutron beam’s extent and divergence, essentially stating that attaining increased flux via an optical device is paid for by increasing the divergence.

Long, elliptic guides, contemporarily utilized for focusing and point-to-point transport of neutrons, can increase the flux at the sample position, but at the same time cause a complex intensity and divergencepattern. In comparison, nested focusing devices provide well behaved flux and divergence distributions, hence their triumph among X-ray telescopes.

Planned arrangement of nested mirror devices, orange insets, at MIRA, incorporated into a MIEZE geometry. © MLZ

During the last beamtime in 2020, we investigated a prototypical nested device (see above), highlighting its usefulness for beam extraction and focusing of neutrons. While the scientists at PUMA just entered the design process for their own nested focusing device, MIRA will be getting theirs in early 2022, just in time to take advantage of the neutrons returning from hibernation and to focus on doing exciting science once again.

C. Herb (TUM)

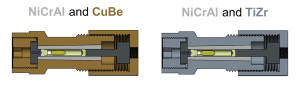

Research with positrons

Although no reactor based positron beam was available in 2021, coincidence Doppler-broadening (CDB) measurements were possible by using the beta+ emitter Na-22 sandwiched between two identical samples.The samples measured include a set of reference samples to benchmark the current device configuration as well as a set of Al alloys in which the behaviour of Cu precipitates after the application of different temper processes was studied.

Operation of the new liquid nitrogen filling system for the high-purity Germanium detectors. © Bernhard Ludewig, FRM II/ TUM

- The read-out of the detectors by multi-channel analyzers with built in signal processing has been improved by a new optimization code.

- Major parts of the liquid nitrogen (LN) cooling system of the high-purity Germanium detectors have been replaced by a new ones.

- A new insert for measurements on gaseous samples was constructed, built and tested in a mockup, which allowed pre-studies for an (applied) project to enable in operando positron beam experiments on samples in humid or/and gaseous atmosphere.

C. Hugenschmidt (TUM)

NeutroSense improves detection

Classical neutron imaging uses detectors which integrate over an exposure time of several seconds to produce transmission images of a sample. Within the framework of the project NeutroSense we are combining a high speed camera, an image intensifier and a highly efficient optical microscope to acquire images fast enough to observe the individual light spots produced by single neutrons. This allows to identify the center of each event with sub-pixel accuracy thus overcoming the limitation in spatial resolution posed by the scintillator. Moreover, highly optimized algorithms using GPU acceleration enable a real-time evaluation of the data strongly decreasing the data rate. Among the many advantages of this event-mode detection approach are the possibility to improve the spatial resolution to the single µm regime, improved signal-to-noise ratio and the possibility to choose the best compromise between spatial- and time resolution after the experiment.

M. Schulz (FRM II)

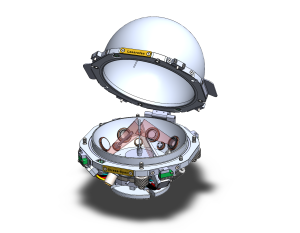

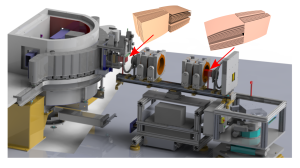

New laser furnace at STRESS-SPEC

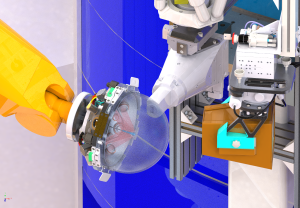

Within the framework of a BMBF funded project to increase the capabilities of the existing 6-axis robot at STRESS-SPEC, a dedicated furnace was foreseen allowing strain and texture measurements at elevated temperatures.

This furnace has a spherical shape to give nearly unhindered access for incoming and scattered neutrons, so that once the furnace is mounted to the flange, the robot can move with the highest possible degree of freedom.

For rapid heating, four infrared laser diodes are installed to achieve a maximum temperature of up to 1300 °C in very short times. You can see the laser rays in the construction drawing.

The furnace has been designed with the help of the central workshop of the TUM Physics Department and initial tests show that already with a single diode, temperatures higher than 800°C can be reached easily. Currently, the control electronics are built in collaboration with MLZ partners from Hereon and we are eagerly awaiting the reactor restart for final commissioning of the furnace with neutrons.

M. Hofmann (FRM II)

People

» Welcome at POLI and HEiDi!» KIT joins PUMA

» Newly arrived

Welcome at POLI and HEiDi!

In July 2021, Prof. Mirijam Zobel took over the chair of the Institute of Crystallography at RWTH Aachen University. Since many years, this institute is involved in the operation of the single crystal diffractometers HEiDi and POLI here at MLZ.

Her recent topics in science are the structure and dynamics of nanostructured interfaces, e.g. structure analysis on nanomaterials, in-situ/operando studies of nucleation and heterogeneous catalysis or the restructuring of solvents and the dynamics of ligands on nanoparticle surfaces.

This is done using X-ray and neutron scattering methods focussing so far on powder diffraction, PDF, SAXS/SANS and QENS.

Up to now our teams on HEiDi and POLI have been very successful in the developments on instrumentation and methods, especially also within third-party funded projects and in cooperation with JCNS, and will focus in the near future, aside from other things, on extensions with area detectors, improved background reduction/correction and polarized powder diffraction.

KIT joins PUMA

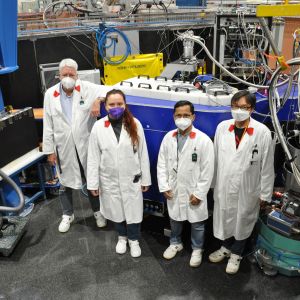

Group members at PUMA: Norbert Jünke, Alsu Gazizulina, Avishek Maity and Jitae Park (from left). © MLZ

PUMA has been constructed and operated jointly by the Göttingen University and the Technical University of Munich from the very beginning of the FRM II. Such long-standing cooperation lasted until the retirement of Prof. Götz Eckold in 2019 (Honour for the Father of PUMA).

From May this year, the Institute for Quantum Materials and Technology (IQMT) at KIT (Director: Prof. Mattieu Le Tacon; Neutron scattering group leader: Dr. Frank Weber) officially joined MLZ as a cooperation partner of PUMA. The IQMT at KIT – formerly Institute for Solid State Physics – has a strong background in inelastic neutron scattering research and instrumentation as they had built and operated a thermal neutron three axes spectrometer (1T) at LLB for more than three decades until the end of the Orphee reactor at Saclay, France.

The neutron scattering group at KIT will engage in instrument development, in-house research, and also for external user supports on PUMA. Alsu Gazizulina is delegated as an instrument scientist and represents the neutron scattering group of IQMT at MLZ.

The PUMA team

Newly arrived

Alexander Book

I am a new member of the Physics Lab and will be responsible for the commissioning and operation of three X-ray diffractometers located above the Neutron Guide Hall East. Additionally to a general purpose diffractometer, we will set up a reflectometer and a residual stress diffractometer.

Before, I worked as a PhD student at the Physics Department of TUM, where I developed a method to uniquely determine the phase information in polarized neutron reflectometery for magnetic thin films – curious? Read more at https://doi.org/10.1016/j.nima.2021.165970!

Lukas Grossmann

As a new member of the Advanced Materials Group at the MLZ, I will investigate novel electrode materials in lithium ion batteries. Therefore, X-ray methods will be combined with various neutron techniques available at the MLZ.

During my PhD, I synthesized and investigated organic 2D materials with the aid of scanning tunneling microscopy and other surface sensitive techniques. In this context, I was able to create a mesoscale-ordered 2D polymer by photopolymerization. If you are interested, please read: https://doi.org/10.1038/s41557-021-00709-y.

Jia-Jhen Kang

Hello everyone! I just joined as the second instrument responsible and a postdoc at the small-angle neutron scattering (SANS) instrument, KWS-2.

I am mainly working on the establishment of the new sample environment – the SEC-SANS setup. This setup combines size-exclusion chromatography (SEC) with SANS, allowing the online separation followed by the collection of scattering data of the protein samples which are prone to aggregate over time. Furthermore, I will be doing the user support during the cycle – I am looking forward to meet the first users in 2022!

Teresa Kiechle

I am a new member of the press and public relations team. Since October, I have been supporting my colleagues in science communication and the external representation of the research neutron source. A special focus there is on developing our social media presence on Twitter, Facebook, Instagram and You Tube.

I have a Master’s degree in Management and Technology from TUM. After three years as a working student at FRM II, I am now very excited to join the team as a regular employee and to promote the science and research at our facility to the public.

Users

» Being present again!» Touring virtually

» Remarks of the MLZ User Committee

Being present again!

From August 14th – 22nd, the Twenty-Fifth Congress and General Assembly of the International Union of Crystallography (IUCr25) took place in Prague, Czech Republic. This conference is one of the most important events for scientists worldwide concerning crystallography and methods/developments on structure studies in all its facets. Due to the pandemic, this conference had been postponed for one year (like so many others) and extended to a hybrid format offering both participation in and presentation of talks and posters in person or online.

Despite the tight programme with eight microsymposia in parallel every day, some of the 400 participants on-site found their way to our booth, where Anatoliy Senyshyn, Chris Garvey and Martin Meven were happy to provide further information about our facility.

M. Meven (RWTH Aachen), A. Senyshyn (FRM II)

Touring virtually

Due to the pandemic, most conferences and meetings were either postponed or held in an online/hybrid format. The User Office was keen to also gain experiences with virtual booths – after so many real-life booths in the last years. To be honest, we were foremost keen to meet our user community again and get in touch with users-to-be…

Thus, while the colleagues enjoyed Czech hospitality at IUCr25 and met in person at the MLZ booth on-site (see above), the User Office took care of the virtual booth there. It was mostly a chatting portal but it was a really nice experience: In total, the 61 exhibition booths had 1033 chats, that’s quite a number!

In the end of September, the DPG called for the annual meeting of the Condensed Matter Section (SKM21). In this (only) online format a nice software was used allowing for “building” a booth and not only chatting with visitors but also making video calls. It was great to see so many users again!

Remarks of the MLZ User Committee

Dear neutron user!

The newly elected II. MLZ User Committee during the first meeting with the MLZ Directorate Peter Müller-Buschbaum and Martin Müller and the MLZ User Office (Ina Lommatzsch): Chair Tommy Nylander, Jens Gibmeier, Ana Bras Würschig, Andrea Scotti, Sandra Cabeza (from top). © MLZ

This has been challenging times for us all. As we slowly try to move back to normal scientific life, we discover that it is more challenging than we thought. Also from the social point of view. In addition, as we thought that the pandemic was all over, it seems to strike back as the winter is around the corner.

From the neutron user perspective, it has not been very good either with all the major European facilities closed, except PSI. We also note that NIST had shut down this year due to an incident, which luckily was manageable.

Our MLZ had quite some bad luck, with first the COVID closure and then the break-down of the cold source. The cold source will take almost two years from now to replace, so for some of us it will be challenging to run neutron experiments at MLZ. The management has decided to make the best of the situation and open-up the facility anyhow without cold neutrons this spring. This will of course limit the performance of some of the key instruments. So the advice is to get in touch with your beamline scientist an ask for an update on the “new” performance.

Despite this somewhat gloomy news, there is some bright things to consider. Next year, ISIS will open its target station 2 in spring, NIST will be opening up in April and SNS in Oakridge will still be opened. And ESS civil constructions will be completed by the end the year, although we have to wait some time before the neutrons will arrive at the target. ICNS 2022 will be in Buenos Aires, (Aug 21st-14th) and the ESS & ILL user meeting will be in Lund (Oct. 05th-07th). So I hope we can meet in person on any of these events.

We wish you all a merry Christmas and a happy and prosperous New Year 2022!

On the behalf of the MLZ user committee.

Tommy Nylander

Welcome to the MLZ Newsletter!

The MLZ Newsletter is sent directly to your inbox. All our users are invited to subscribe to it via GhOST!

You aren’t a scientific user but interested? Then just send an email to the MLZ User Office!

MLZ ist eine Kooperation aus:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ ist Mitglied in:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ in den sozialen Medien: