MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

SPODI

High resolution powder diffractometer

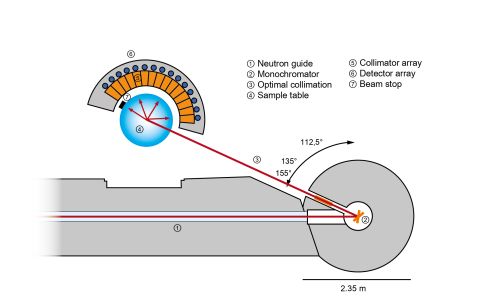

The high-resolution powder diffractometer SPODI is designed for structure solution and Rietveld refinement of structural parameters on crystalline powders. The instrument has a very high monochromator take-off angle of 155° (standard configuration). Optionally, a take-off angle of 135° is available.

The detector array comprises 80 3He position-sensitive detector tubes (300 mm active height) with fixed Soller collimators of 10’ horizontal divergence. The multidetector of SPODI spans an angular range of 2θ = 160°. Each detector covers 2°, corresponding to 160°/ 80 detectors. Therefore, the data collection is performed via stepwise positioning of the detector array to obtain a diffraction pattern of the desired step width (typically 2°/ 40 steps resulting in Δ(2θ) = 0.05°).

The two-dimensional raw data is evaluated to provide diffraction patterns corresponding to different detector heights ranging from 10 mm to 300 mm and ‘variable detector height’ (= optimum compromise between intensity and resolution by software), accounting for vertical beam divergence effects. Thus, asymmetric broadenings at quite low and high scattering angles are overcome, while the full detector height in the medium 2θ regime can be used [1].

Various sample environmental devices enable the characterisation of materials under special conditions: A rotatable tensile rig allows in-situ studies under tensile stress, compression stress, or torsion while the load axis can be oriented with respect to the scattering plane. A potentiostat for charging/discharging Lithium-ion batteries and a device to apply high electric fields on ferroelectrics are available.

[1] Hoelzel, M. et al., NIM-A 667, 32 (2012).

- Determination of complex crystal and magnetic structures

- Structural evolutions and phase transformations under various environmental conditions

- Static and thermal disorder phenomena

- Ion conductors, e.g. oxygen conductors

- Materials for electrochemical energy storage, e.g. lithium-ion batteries

- Ferroelectrics, multiferroics

- Hydrogen storage materials

- Shape memory alloys

- Turbine materials

- Correlated electronic systems

- Superconductors

- Minerals and geological samples

- Closed cycle cryostat: 3 – 320 K

- With 3He insert: Tmin = 500 mK

- With heating option Tmax = 550 K

- Vacuum high-temperature furnace: Tmax = 1700°C

- Cryomagnet

- Bmax at SPODI: 5 T

- Sample changer: ten samples, ambient temperature

- Rotatable tensile rig

- Fmax = 50 kN

- Mmax = 100 Nm

- Device for electric fields: Vmax = 35 kV

- Potentiostat for electrochemical treatment of materials, VMP3 and SP240 from BioLogic

- Ge(551) wafer stack crystals

- Standard configuration: take-off angle 155°

- Ge(551): 1.548 Å

- Ge(331): 2.536 Å

- Ge(711): 1.111 Å

- α1 ≈ 20’ (neutron guide)

- α2 = 5’,10’, 20’, 25’ nat. (for 155°)

- α2 = 10’, 20’, 40’ nat. (for 135°)

- α3 = 10’

- 80 position-sensitive 3He tubes

- Angular range 2θ = 160°

- Effective height: 300 mm

DISEMM (Diffraction assisted mechanical modelling)

The software DISEMM is designed to analyse diffraction data from in-situ loading experiments to obtain diffraction elastic constants and single-crystal elastic constants as well as to describe the mechanical behaviour of the elasto-plastic self-consistent modelling.

DISEMM offers a variety of grain-to-grain interaction models and integrates texture and multi-phase alloys.

Heldmann, A. et al., J. Appl. Crystallogr. 52 (5), 1144 (2019).

DOI: 10.1107/S1600576719010720

The software is currently available for Windows.

The download provided here offers a .zip file consisting of libraries and the executable, just unpack and you are ready. The DISEMM software code can be found on github, you can get the corresponding manual here.

Instrument scientists

Dr. Markus Hölzel

Phone: +49 (0)89 289-14314

E-mail: markus.hoelzel@frm2.tum.de

Dr. Anatoliy Senyshyn

Phone: +49 (0)89 289-14316

E-mail: anatoliy.senyshyn@frm2.tum.de

Dr. Christoph Hauf

Phone: +49 (0)89 289-14435

E-mail: christoph.hauf@frm2.tum.de

SPODI

Phone: +49 (0)89 289-14826

Operated by

Funding

News

Publications

Find the latest publications regarding SPODI in our publication database iMPULSE:

Citation templates for users

In all publications based on experiments on this instrument, you must provide some acknowledgements. To make your work easier, we have prepared all the necessary templates for you on this page.

Instrument control

Gallery

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: