MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

POWTEX (under construction)

High-intensity time-of-flight diffractometer

The high-intensity TOF diffractometer POWTEX is designed and built by RWTH Aachen University and Forschungszentrum Jülich. The University of Göttingen cooperates by developing the texture analysis and by providing additional sample environments. Both projects have been granted by the German Federal Ministry of Education and Research (BMBF). POWTEX will be part of the JCNS instrumentation pool.

POWTEX is an acronym for POWder and TEXture because the instrument will fulfil the needs of solid-state chemistry, geoscience, and materials science communities with regard to powder and texture diffraction.

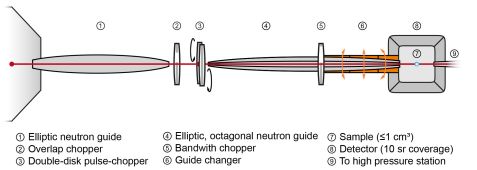

The instrument design combines several new concepts. The neutron guide system consists of two double-elliptic parts with a common focal point of

In order to produce sharp pulses of 10 µs, the pulse chopper uses two counter-rotating discs at 200 Hz and a short distance of only 0.5 cm. A variation of the chopper settings allows a flexible time structure to change the wavelength band or the pulse frequency (pulse-overlap mode like at POLDI, PSI yields a ten times higher intensity).

Because of the 3He shortage, two new detector developments were initiated (6LiF-WSF and 10B-Jalousie). While both prototypes successfully passed a test beam time, the 10B-Jalousie detector was chosen as the future POWTEX detector concept. The detector design will cover a huge solid angle (10 sr), and its dimensions will allow large sample environments (e.g. in situ experiments). The high detector coverage is of particular importance for texture measurements because it avoids the need for tilting the sample. Furthermore, it allows texture measurements without sample rotation (without sample environment), and it reduces the number of sample rotations with sample environment. It allows simultaneous strain/stress/texture measurements and recrystallisation analysis. For powder diffraction, the covered solid angle relates directly to the efficiency/measurement time. With the three-dimensional (2θ, TOF, intensity) diffractograms and adapted data treatment, POWTEX will simultaneously benefit from the higher resolution in back-scattering and the high intensity at lower angles.

[1] Houben, A. et al., NIM-A, , 680, 124 (2012).

The high intensity will allow comparatively short measurement times and a high sample throughput.

- Crystallographic and magnetic structure determination

- Multiphase analysis using the Rietveld method

- In situ experiments, e.g., on chemical reactions

- Phase transitions as a function of T, p, B0, etc.

- Parametric studies

- Simultaneous stress/ texture measurements

- In situ deformation (also long-time experiments)

- Recrystallisation/ annealing experiments

A tailored set of sample environments is inevitable to avoid shadowing the detector.

To benefit from the short measurement times, a cryo-furnace with a temperature range from 10 to 700 K, including a sample changer, is planned.

Our colleagues at the University of Göttingen and the MLZ design a mirror oven for temperatures up to 2000 °C which can be operated with inert or reactive gases.

Göttingen University also designs sample environments for specific geoscience applications, e.g., a unique uniaxial and triaxial deformation apparatus.

Beam layout

- Thermal neutrons on beam tube SR-5a

- NL1: double elliptic with m = 1.75 – 5.25; quadratic cross-section

- NL2: double elliptic with m = 2.00 – 5.00; octagonal cross-section

- Divergence ≈ 0.33° – 0.66°

Chopper system

- Double-disk pulse-chopper as needle eye; sharp

10 µs pulses; background reduction - CFK disks with 75 cm diameter on magnetic bearings

- Standard range of λ = 1.0 – 2.4 Å

- Wavelength bandwidth: Δλ = 1.4 Å (flexible range selection)

- Pulse duration ≈ 10 µs

- Pulse frequency 200 (standard) to

2000 Hz (pulse overlap mode)

Detector

- Coverage: 2θ ≈ 10 – 170° (10 sr)

- d-Range ≈ 0.5 – 12.5 Å

- Sample detector distance = 80 cm

- Spatial resolution ≈ 5 × 5 mm2

Instrument Scientist

Dr. Andreas Houben

Phone: +49 (0)241 80-90061

E-Mail: andreas.houben@ac.rwth-aachen.de

Dr. Werner Schweika (JCNS)

Phone: +49 (0)2461 61-6650

E-Mail: w.schweika@fz-juelich.de

Dr. Jens Walter (GZ Göttingen)

Phone: +49 (0)551 39-33196

E-Mail: jwalter@gwdg.de

Operated by

Funding

News

Publications

Find the latest publications regarding POWTEX in our publication database iMPULSE:

A. Houben, Y. Meinerzhagen, N. Nachtigall, P. Jacobsb, and R. Dronskowskia

POWTEX visits POWGEN

J. Appl. Cryst. (2023). 56, 633–642

10.1107/S1600576723002819

Citation templates for users

In all publications based on experiments on this instrument, you must provide some acknowledgements. To make your work easier, we have prepared all the necessary templates for you on this page.

Instrument control

Gallery

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: