MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

Elastic Scattering

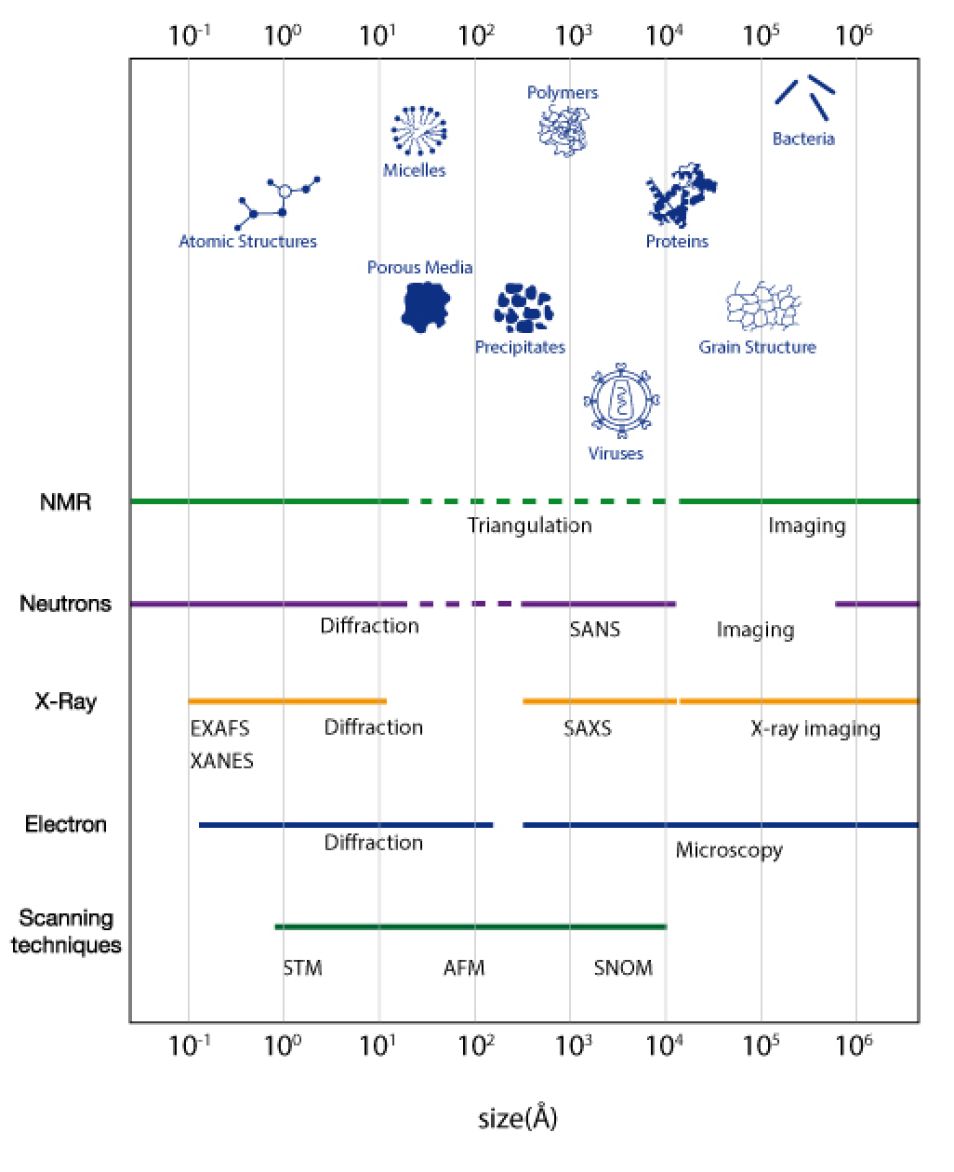

In an elastic scattering process, the neutron is scattered by nuclei or magnetic moments in samples without changing its energy. Elastic neutron scattering is used to investigate the atomic and magnetic structure of materials, depending on the interaction of the neutrons with the nuclei and magnetic moments in the sample. While wide-angle diffractometers (single-crystal diffractometers, powder diffractometers, materials science diffractometer) are able to analyze materials on the atomic scale, small-angle scattering instruments and reflectometers access nano- to mesoscopic structures.

Diffraction

Despite the totally different nature of interactions, neutron diffraction is often compared to X-ray diffraction. Hence as an isotope-sensitive technique, neutron diffraction has numerous advantages, especially in the area of localizing light elements and distinguishing neighbouring elements in the periodic table. The magnitude of magnetic dipole-dipole interaction in neutron diffraction is comparable to strong-force interaction, which makes this technique useful for the determinatiaon of different kinds of magnetic orders.

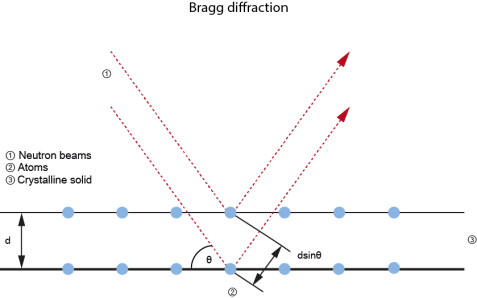

In a diffractometer, the intensity of the scattered neutrons is measured as a function of the scattering angle. Constructive interference can be described by

Bragg’s law:

with integer n, wavelength of the neutron λ, interplanar distance d and scattering angle 2θ.

With a typical wavelength of λ = 0.05 – 2 nanometer (1 nm = 10-9 m), the same order of magnitude as interatomic distances (≈ 0.15 nm), neutrons are a valuable tool to determine the arrangement of atoms in hard condensed matter. Besides the positions of the atoms (crystallographic structure), a possible order of magnetic moments (magnetic structure) can also be elucidated along with different kinds of static and thermal disorder phenomena.

The knowledge of a material’s structure is crucial for the understanding of the relationship between the structure and properties of any material. The diffraction experiments can be performed on samples with periodic atomic arrangement in different forms, e.g. single crystals, bulk polycrystalline materials and powders.

A single crystal is the highest type of condensed matter organization and diffraction studies usually give the most accurate structural information. The 3-dimensional periodic arrangement of atoms or molecules in crystals enables the detection of distinct diffraction signals (Bragg reflections) coming from the large number of lattice planes existing in the crystal. This usually allows the detection of a large number of independent Bragg-reflections up to high diffraction angles. This significantly enhances the accuracy of the obtained structural information (symmetry, cell metrics, atomic positions and site occupancies, displacement parameters, orientation of magnetic moments etc.) as well as making it a perfect tool for the determination of very complex atomic arrangements. The data collection of a large number of reflections makes this technique time-consuming, which along with the need for single crystals are the major restrictions in single crystal neutron diffraction studies.

Typical research areas usually include new materials and minerals, ferroelectrics and multiferroics, strongly correlated electron systems, macromolecular crystals, protein structures etc.

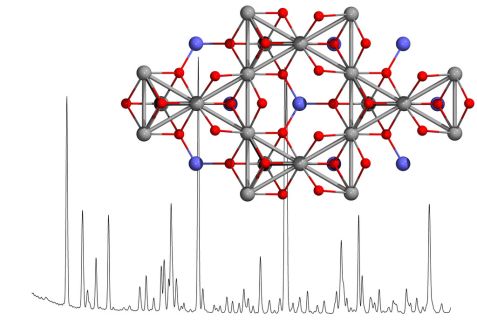

Part of real neutron powder diffraction pattern and the fragment of crystal structure for Co10Ge3O6 frustrated magnet with cobalt, germanium and oxygen shown by gray, blue and red, respectively (Picture: SPODI, FRM II)

In contrast to single crystal diffraction, a huge practical advantage of powder diffraction is that chemical compounds are much more easily obtained in the form of a powder or polycrystalline bulk sample rather than in the form of a single crystal. Randomly-oriented crystallites (powder grains) lead to an overlapping of diffraction signals from different lattice planes with the same interatomic spacings. This results in a reduced number of independent observables, but makes the data collection process significantly faster and simpler. Therefore powder diffraction studies typically examine the structural or magnetic subsystem of polycrystalline materials under the influence of external parameters (temperature, pressure, magnetic field, mechanical force, electric field etc.) by monitoring their evolution “live”. These features, along with the fact that the compositional sample proof (phase analysis) can be performed both quantitatively and qualitatively, make the powder diffraction especially powerful in the characterization of new materials.

Research areas typically include materials for lithium-ion batteries, ionic conductors of different kinds, ferroelectrics and multiferroics, hydrogen storage materials, engineering alloys, superconductors and strongly correlated electron systems, minerals and geological samples.

In the field of material science and engineering, the demand for specially dedicated diffractometers able to perform different kinds of deformation, phase transformation, residual stress, texture, and microstructure studies is very high. By design, materials science diffractometers are very flexible. Typical machines in this class cover a wide range of applications in materials science and engineering, e.g. in the determination of residual stress in engineering components to understand the fundamental aspects of the behaviour of materials during synthesis, processing, and service. Spatially-resolved diffraction (exploring excellent neutron penetration into the matter) allows the monitoring of structural changes deep inside bulky samples far beyond the depth accessible with X-ray diffraction. Different kinds of load frames, furnaces and other auxiliary equipment are used for the in situ characterization of materials. Materials science diffractometers are nowadays mostly employed for residual stress analysis and texture investigations in technically relevant alloys and composites.

Other elastic neutron scattering techniques

For the study of large-scale structures at a mesoscopic scale of about 1 – 1000 nm small-angle neutron scattering (SANS) and reflectometry are employed.

Small-angle neutron scattering (SANS) at small scattering angles enables the study of large-scale structures or structural inhomogenities in the range of 1 – 300 nm. SANS-Instruments obtain information about the size, shape and orientation of the components and magnetic properties in a sample.

SANS provides valuable information over a wide variety of scientific and technological applications including, for instance, the study of soft matter materials (e.g. polymers, macromolecules, biological samples), determination of morphology, size and volume of precipitates in metal alloys, study of chemical aggregation or investigation of magnetic microstructures in nanocrystalline and bulky material.

Neutron reflectometry measures the reflected neutrons under very small incident angles (θin) to investigate nanometer to micrometer thin films at interfaces (media with a different refractive index for neutrons, n0 ≠ n1). The measurement of the in-plane (ψ = 0) reflected specular intensity (θin = θsc) as a function of the incident angle and/or wavelength (λ) yields information only about the nuclear and magnetic scattering length density profile normal to the surface (along the z-axis).

To investigate lateral structures (in the x-y-plane) such as roughness, (magnetic) domains, vortices in superconductors and clusters of the reflecting interface in the range of several µm in-plane off-specular scattering (ψ = 0, θin ≠ θsc) is used.

For lateral structures in the x-y plane in the order of atomic distances (down to few Å) at the surface, grazing incidence neutron diffraction (GIND) is employed. Here, the scattered neutrons out of plane (ψ ≠ 0) are counted while Θin is constant.

Neutron reflectometry provides valuable information in a wide q-space and over a wide variety of scientific as well as technological applications such as polymer and surfactant adsorption at solid or liquid interfaces, chemical aggregation, and chemical depth profile, structure of polymer films, lipid bilayers in biological membranes, magnetic ultrathin films and multilayers.

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: