MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

On the hunt for lead-free ferroelectrics using neutron diffraction

In many technical products – from car engines to loudspeakers – components made from so-called ferroelectric materials can be found. Due to their special properties, they make up the basis constituent of transducers and sensors. However, the ferroelectric materials in use today often contain lead. In the search for lead-free alternatives, neutron diffraction techniques can be of help. The ability of neutrons to deeply penetrate materials can be used to great advantage, while facilitating the investigation of large samples.

Piezoelectric materials make it possible to convert energy from mechanical to electrical and vice versa. In ferroelectrics, a subgroup of piezoelectrics, the electric polarisation can be switched by means of an external electric field. Ferroelectric ceramics find extensive applications as actuators, sensors or transducers, for example in fuel injectors, loudspeakers, microphones, strain gauges, ultrasound transducers for medical imaging or materials testing, sonar equipment, piezo motors and guitars. Additional electronic applications include capacitors and ferroelectric RAMs.

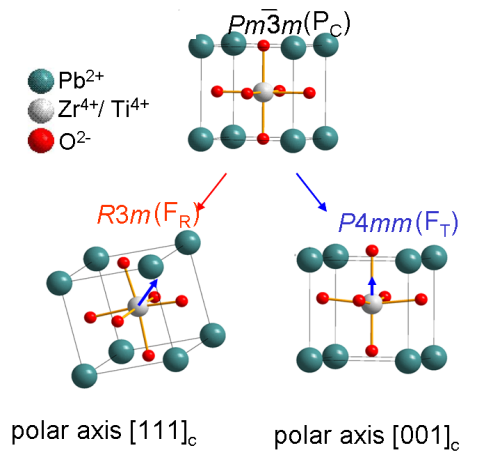

Technical ferroelectrics are typically based on lead zirconate titanate (PbZr1-xTixO3 or PZT for short). The piezoelectric properties depend on the crystallographic structure – that is the arrangement of the atoms in the material. In particular the electric field-induced strain or field-induced polarisation – can be tuned by varying the titanium/zirconium ratio or adding doping elements for titanium and zirconium (such as iron) or lead (such as lanthanum). At room temperature, lead zirconate titanates with a high zirconium content exhibit a rhombohedral structure, while titanium-rich samples have a tetragonal symmetry (Fig. 1). In so-called phase diagrams, which display the structures of PZT depending on composition, the rhombohedral and tetragonal phase regions are separated by the so-called morphotropic phase boundary.

In recent years, the toxicity of lead oxide and its high vapour pressure during processing initiated a search for alternative lead-free, environmentally-friendly piezoelectric materials. In this respect, materials based on the system Bi0.5Na0.5TiO3 -BaTiO3-K0.5Na0.5NbO3 (BNT-BT-KNN) are quite promising. Similar to PZT, the phase diagram of the system BNT-BT-KNN also shows a morphotropic phase boundary, separating a rhombohedral and a tetragonal phase.

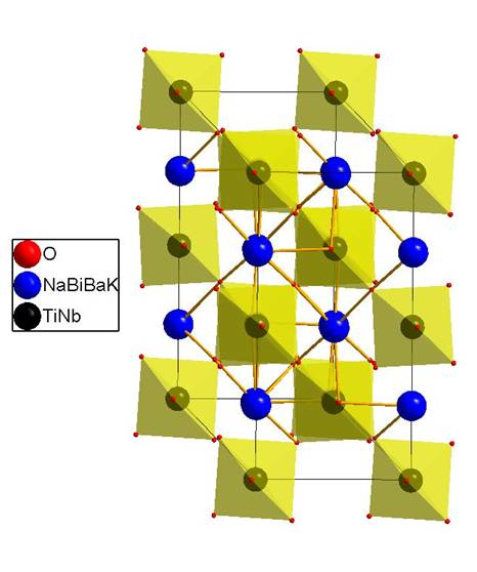

![Fig 2: Structure of 92% Bi0.5Na0.5TiO3 - 6% BaTiO3 – 2% K0.5Na0.5NbO3 at an electric field of 6 kV/mm. View along the crystallographic [100] direction. The distorted octahedra (with titanium/niobium atoms at the centre and oxygen atoms at the corners) are highlighted.](index.php?rex_media_type=content_half &rex_media_file=octahedra.png)

Fig 2: Structure of 92% Bi0.5Na0.5TiO3 - 6% BaTiO3 – 2% K0.5Na0.5NbO3 at an electric field of 6 kV/mm. View along the crystallographic [100] direction. The distorted octahedra (with titanium/niobium atoms at the centre and oxygen atoms at the corners) are highlighted.

For both systems PZT and BNT-BT-KNN, it is well known that compositions around the morphotropic phase boundary exhibit outstanding piezoelectric properties. Despite an abundance of research on these materials, controversy on the structure at the morphotropic phase boundary for both systems PZT and BNT-BT-KNN still exists. In particular, the structural changes occurring during the the re-orientation of the polarization under the influence of an electric field are debated. Knowledge of these structural changes is of crucial importance in the understanding of the mechanisms of the re-orientation or “poling” process.

Neutron diffraction studies on technical ferroelectrics under electric field enable investigations to be carried out into the structural changes under poling conditions. As an example, in two compositions of the system BNT-BT-KNN, the large field-induced macroscopic strain could be explained by a phase transformation during the poling process [1]. In both cases, the transition to a rhombohedral phase was identified by corresponding superlattice reflections, arising from a superstructure due to the tilting of the oxygen octahedra around titanium or niobium atoms (Fig. 2,3).

In general, various contributions to the ferroelectric response should be considered, such as atomic displacements, domain switching processes and structural phase transformations. Based on this knowledge, materials with optimised properties for distinct applications can be designed, such as actuators with very high field-induced strain.

Neutron diffraction is advantageous with respect to X-ray diffraction for a precise localization of oxygen atoms. The large penetration depths of neutrons permit the study of large bulk samples such as technical actuators. In addition, the large penetration depths of neutrons facilitate experimental setups whereby samples can be investigated using different directions of the applied electric field with respect to the incident beam and/or different temperatures.

References:

[1] M. Hinterstein, M. Knapp, M. Hoelzel, Wook Jo, A. Cervellino, H. Ehrenberg, H. Fuess, “Field induced phase transition in lead-free 0.92BNT-0.06BT-0.02 KNN”, J. Appl. Cryst. vol. 43, pp. 1314-1321, 2010.

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: