MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

06.07.2018

New material could cut down the cost of medical imaging

Dr. Rajeev Ranjan and Dr. Anatoliy Senyshyn (r.) during their measurements at the instrument SPODI of MLZ. © W. Schürmann / TUM

Indian researchers have engineered a piezoelectric ceramic with the highest shape changing value reported so far for polycrystalline ceramics and close to the record set by single crystals. Using neutron scattering at the instrument SPODI, they could explain the mechanism of the new material.

This ceramics sounds like the dream of a material scientist: It could be used in automotive industry, medical imaging, guidance systems and many more. It would be easier to produce and presents a less expensive alternative to materials currently used in industry. Its discoverer, Prof. Dr. Rajeev Ranjan, is full of hope and enthusiasm when explaining the properties of this new piezoelectric material, whose structure was also examined using neutrons at the MLZ instrument SPODI.

Piezoelectric material elongates or contracts under an electric field and can also convert pressure into voltage: In everyday life, each electronic lighter contains a piezoelectric material to spark the fire from pressing the button. But there are more sophisticated uses of these tiny converters of energy: They are for example used in ultrasound imaging, translating voltage into vibration and thus creating sound. In the automotive sector, they are used for the controlled injection of fuel in the engine. The precise movements on the scale of nanometers (used for example in the Hubble telescope) are guided by piezoelectric materials as well.

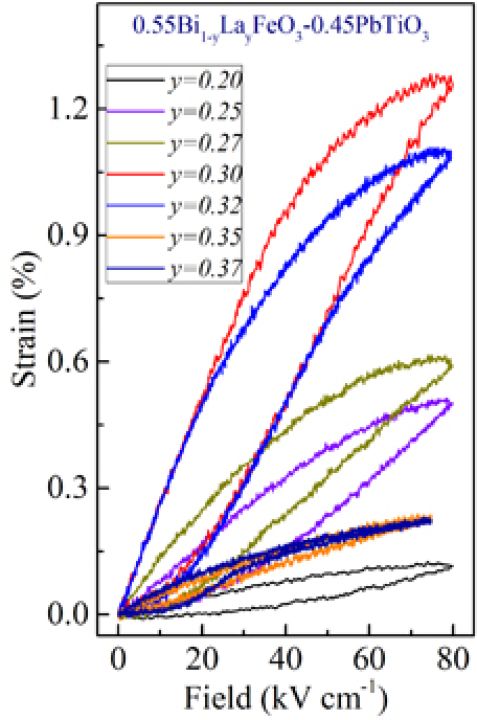

An important performance parameter of such materials is the electrostrain, which is a measure of how much the material‘s length change in proportion to their original dimension under an electric field. While large electrostrain can be achieved in single crystals of certain ferroelectric oxides, their polycrystalline version, which are simpler to produce and up to hundred times less expensive, usually achieves much smaller electrostrain values. Single crystal piezoelectric materials have set the new benchmark to 1.7% of electrostrain, whereas the highest value in polycrystalline materials was up to 0.7% by now. But the ceramic discovered by Rajeev Ranjan showed a value of 1.3%!

Accidental discovery

The discovery was an accident. When Rajeev Ranjan’s PhD student in Bangalore, Bastola Narayan, mixed a new material of lanthanum modified bismuth iron oxide with lead titanium oxide, he was actually looking for a completely different phenomenon, namely multiferroicity. But the new mixture did not keep its promise. „We lost interest“, says Rajeev Ranjan. However, when performing routine measurements in the laboratory, the material scientists at Bangalore found extremely high values for electrostrain: 1.3%, almost double the value of other polycrystalline ceramics designed up to now. „We repeated the measurements as we could not believe our eyes“, says the Associate Professor at the Indian Institute of Science. And then they examined the structure of BiFeO3-PbTiO3-LaFeO3 closer, using neutrons in combination with other characterisation methods.

At the neutron powder diffractometer SPODI in Garching, Rajeev Ranjan aimed to understand the structure of the ceramics at the nanoscale. TUM instrument scientist Dr. Anatoliy Senyshyn, who is a collaborator in this work and also his host for a 3 months Humboldt fellowship until end of June 2018, performed the measurements. „Only neutrons could give us additional information about the oxygen twist in the structure“, explains Rajeev Ranjan. „With the low background at SPODI, we could detect very subtle features in the neutron diffraction data which helped in explaining the mechanism of the extremely large electrostrain in this material.“ Rajeev Ranjan is currently obtaining a patent protection for the new ceramics in India.

Original publication:

Bastola Narayan, Jaskaran Singh Malhotra, Rishikesh Pandey, Krishna Yaddanapudi, Pavan Nukala, Brahim Dkhil, Anatoliy Senyshyn & Rajeev Ranjan

Electrostrain in excess of 1% in polycrystalline piezoelectrics

Nature Materials, 17, 427 (2018)

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: