MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

14.07.2021

Metals with memory

As in the case of a beverage can, which is first pressed in sideways and then returns to its original shape, a force initially acts horizontally on the specimen in the case of the magnetic shape memory alloy. The magnetic field in the vertical direction restores the original shape. © Reiner Müller / FRM II, TUM

When metallic objects change their shape seemingly without any external influence and only according to the will of their owners, this at first sounds like something only comic superheroes like Magneto and Ironman could do. However, the idea from those comics has a real-world manifestation in existing materials called magnetic shape memory alloys (MSMAs). Moreover, they have potential applications e.g. in robotics or medical devices.

MSMAs are metals that can change their geometric shape in response to an external magnetic field or temperature. Responsible for this is the coexistence of two perpendicular, slightly deformed crystal lattices (so-called twins). Under normal pressure or magnetic field, the two twin phases are in equilibrium. However, when a relatively low pressure is applied to the material, one of the two phases is favored, and the metal deforms. If a magnetic field is now applied, the magnetic domains start to reorient and force the material to assume its original geometry – the so-called magnetic shape memory effect.

This interesting interaction between mechanical stress and magnetism opens up a wealth of potential applications ranging from robotics to medical- and sensor technology.

Precise mechanism is unknown

The macroscopic effect of magnetic shape memory has been known for a long time; however, the exact microscopic mechanism of magnetization in MSMAs remained controversial. One of the most efficient methods to investigate this question is diffraction with polarized neutrons, as for example with the instrument POLI at MLZ. For this purpose, the sample under investigation is situated in a magnetic field and the incoming neutron beam is prepared in the way that all magnetic moments of the individual neutrons are aligned along the field direction. As such, they are called “polarized neutrons” because they have magnetic polarity in specific directions. Polarized neutrons then act like microscopic compass needles that can sense individual magnetic atoms in the sample and distinguish them from the magnetic domain walls.

In MSMAs materials, the magnetic field also causes the motion of the twin phases, making it impossible to separate them from the motion of the purely magnetic domains. An international team of scientists from the University of Hong Kong came up with the idea of performing a polarized diffraction experiment with simultaneous application of mechanical stress. “This allowed us to study the interaction of the applied pressure and magnetic field in the MSMA in detail, and for the first time distinguish between them clearly at the atomic level.” said Dr. Vladimir Hutanu, a crystallographer at RWTH Aachen University and instrument scientist on POLI, an instrument jointly operated by RWTH Aachen University and Forschungszentrum Jülich at MLZ.

Unique measurement setup

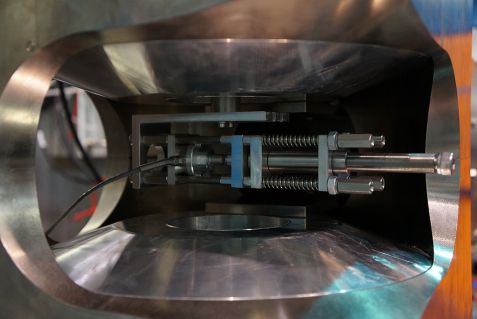

With this apparatus, mechanical stress could be applied in addition to a magnetic field. © Vladimir Hutanu

Simultaneous application of a magnetic field and mechanical stress is difficult to implement in practice. In their search for a suitable research facility, the Chinese scientists became aware of the POLI instrument at the MLZ. Here, a novel high-temperature superconductor magnet with sufficient internal space for large pressure mechanics at the sample location was constructed and implemented for polarized neutron diffraction in 2017. This unique setup made it possible to successfully conduct the experiment.

It allowed the scientists to distinguish between the motion of the twin phases and that of the magnetic domains, providing the insights into the microscopic magnetization processes of MSMA within the single domain. “This knowledge makes it possible to develop new MSMAs for different applications,” says Vladimir Hutanu. The researchers published their findings in the prestigious journal Applied Physics Letters. Those results and the acquisition of a better understanding of these unique materials was possible to obtain only because the experimentalists were able to set up this complex apparatus at the sample site inside the magnet in the neutron beam. Dr. Jürgen Peters, responsible for the sample environment at MLZ, says, “We are constantly working to expand the available arsenal of methods for neutron scattering and to implement complex sample experiments that were impossible just a few years ago.”

Original publication:

Y. B. Ke, S. Lan, Y. Wu, H. H. Wu, V. Hutanu, H. Deng, A. Pramanick, Y. Ren, and X.-L. Wang. Unraveling magneto-structural coupling of Ni2MnGa alloy under the application of stress and magnetic field using in situ polarized neutron diffraction. Appl. Phys. Lett. 117, 081905 (2020) DOI: 10.1063/5.0016278

Related News

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: