MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

Tailored polymer additives for wax crystal control in petrochemical products

The ability to maintain the transportation of goods and people in an efficient and reliable fashion, even under difficult climatic conditions, has a high impact on the quality of life. Research with neutrons contributes to this by facilitating the development of tailored polymer additives that prevent unwanted precipitation or gelation of waxes in diesel fuels and other petrochemical products at low temperatures.

Crude oils and middle distillate fuels

Crude oils and refined middle distillate products such as diesel fuels, kerosene (jet fuel) or heating oil contain an important fraction of paraffins (alkanes) with a broad chain length distribution. Depending on the type of crude deposits and refined technology applied, this fraction can vary between 10% and 30%.

Aggregate formation at low temperatures

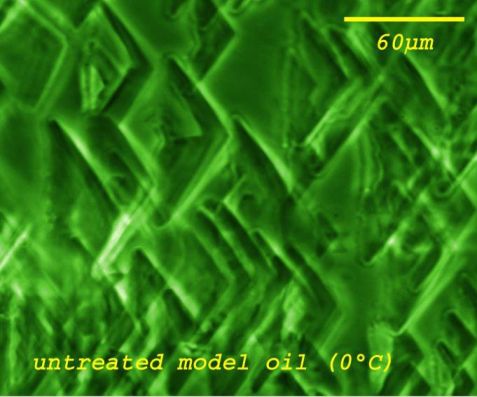

Although in terms of energy, they are desirable because of their increased combustion enthalpy, the long chain of C18-C40 n-paraffins (waxes) in these oils and middle distillates have the disadvantage of forming big crystalline aggregates at low temperatures. During the extraction of these crude oils from deep sea reservoirs or during transport through cold regions, such fluids undergo a dramatic degradation of viscoelastic properties. A drop in temperature causes the precipitation or gelation of waxes and thus the reduction of their solubility (fig. 1). Aggregate formation in crude oils or fuels may plug pipelines, affect the storage tanks or clog filters of diesel motors.

Polymer additives control wax crystallization

To prevent this behaviour, various additives have been developed. These are polymeric systems made of crystalline and amorphous segments able to moderate the wax crystals’ morphology so that crude oils and middle distillates remain fluid at low temperatures. However, the synthesis and choice of such additives are largely trial and error rather than based on scientific principles. A good knowledge of the wax-polymer interaction mechanism on the microscopic scale assesses the ability of an additive to efficiently control wax crystallization and enables the tailoring of additives for specific oil and middle distillate compositions.

Small-angle neutron scattering (SANS) at FRJ-2 and FRM II

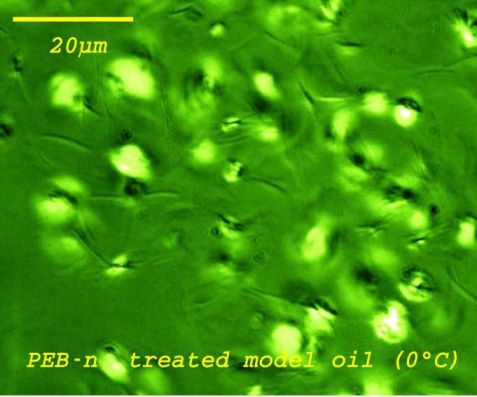

Small-angle neutron scattering (SANS) is a dedicated technique to characterize complex morphologies such as those occurring in a ternary wax-polymer-oil system. Systematic structural SANS studies on specific polymers have provided information used in part for the formulation of the diesel fuel additives Paraflow™ (Infinium, Ltd.) [1]. Results of extensive SANS studies at the neutron sources FRJ-2 (Jülich) and FRM II (Garching) have demonstrated that polymeric systems exhibiting graded crystallinity along the chain may represent optimally efficient and versatile additives for waxy crude oils and petrochemical products [2-5]. Specifically designed polymers are able to template and control the wax crystallization in medium- sized soft aggregates (Fig. 2), thus arresting the growth of large compact waxy crystals and preventing wax gelation.

Original publication

[1] D.Richter et. al, Macromolecules, 30 (4), 1053-1068, 1997;

[2] A.Radulescu, et.al, Macromolecules, 39 (18), 6142-6151, 2006;

[3] A.Radulescu, et.al, Advances in Polymer Science 210, 1-100, 2008;

[4] A.Radulescu, et.al, Journal of Polymer Science B: Polymer Physics, 49 (2), 144-158, 2011;

[5] A.Radulescu et.al, in Crude Oil Emulsions – Composition and Characterization, Ed.M.S.Abdel-Raouf, pp.205-230, Intech, 2012.

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: