MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

Variant redistribution in a Ni-Mn-Ga shape memory alloy during thermo-mechanical treatment

Z. B. Li1, Y. D. Zhang2,3, W. M. Gan4, M. Hofmann5, C. Esling2,3, X. Zhao1, L. Zuo1

1Key Laboratory for Anisotropy and Texture of Materials (Ministry of Education), Northeastern University, Shenyang, China

2Laboratoire d’Étude des Microstructures et de Mécanique des Matériaux (LEM3), Université de Lorraine, Metz, France

3Laboratory of Excellence on Design of Alloy Metals for low-mAss Structures (DAMAS), Université de Lorraine, Metz, France

4German Engineering Materials Science Centre (GEMS), Helmholtz-Zentrum Geesthacht, Geesthacht

5Heinz Maier-Leibnitz Zentrum (MLZ), Technische Universität München, Garching

Single crystal NiMnGa alloy can generate large magnetic-field-induced shape change due to variant reorientation. Apparently, the high-cost fabrication of single crystals constitutes a severe obstacle for practical applications. In contrast, preparation of polycrystalline materials which can generate a large magnetic field-induced shape change due to variant reorientation is much simpler and of lower cost. However, the random distribution of crystallographic orientation in polycrystalline material greatly weakens the orientation dependence of magnetocrystalline anisotropy, which severely impairs the functional properties. Thus, microstructure texturing with proper processing routes could be seen as the best means of recovering the lost anisotropic features. Thermo-mechanical treatment (TMT) incorporating three cycles of uniaxial compression was introduced during martensitic transformation to modify the variant distribution of a polycrystalline Ni50Mn30Ga20 alloy. The phase transformation processes under uniaxial compression were traced by in-situ neutron diffraction, and direct evidence of the variant redistribution was observed.

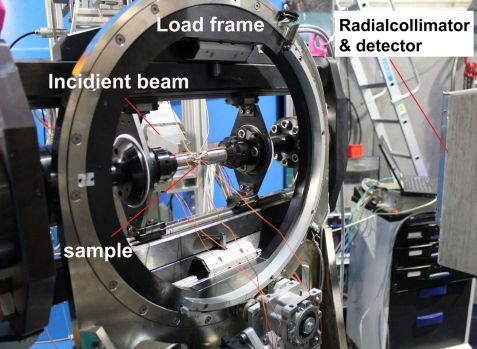

In-situ TMT and neutron diffraction experiments

Uniaxial compressive load was applied via a rotatable multifunctional (tension/compression) load frame installed at STRESS-SPEC [1, 2], using the “constant load” mode to ensure a fixed load. For the in-situ measurements of cyclic thermo-mechanical load, one cylindrical-shaped sample of polycrystalline Ni50Mn30Ga20 alloy was first heated from room temperature (RT) to 393 K to reach the fully austenitic state. Then, a uniaxial compressive load of -10 MPa was applied along the solidification direction (SD). Finally the sample was cooled to RT at a cooling rate of 2 K/min under constant load, during which neutron diffraction images were continuously recorded at an interval of 60 s by a two-dimensional (2D) detector at 2θ = 43.5°. These two steps were considered as constituting Cycle 1 of the TMT. For Cycle 2 and Cycle 3, the experimental conditions were the same as those of Cycle 1, except that the constant compressive load was increased to -25 MPa and -50 MPa, respectively. The experimental setup is shown in Fig. 1.

Martensitic transformation

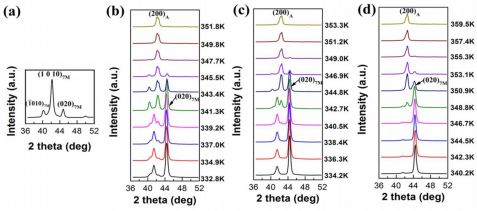

Presently, directionally solidified Ni50Mn30Ga20 alloy, having a martensitic start temperature MS = 347.8 K was determined from DSC measurements. Powder XRD analyses show that the alloy consists of a seven-layered modulated (7M) martensite at RT, having a monoclinic incommensurate superstructure [3]. In this superstructure, the easy magnetization axis of the 7M martensite corresponds to the b axis of the superstructure, i.e. [010]7M.

The diffraction patterns on cooling across the martensitic transformation under the compressive load of -10 MPa (Cycle 1), -25 MPa (Cycle 2) and -50 MPa (Cycle 3), are shown in Fig 2, respectively. The compressive loading induced that the strongest diffraction peak of the 7M martensite, which changed from (1010)7M to (020)7M in the measured 2θ range. After three treatment cycles almost only the (020)7M diffraction remained, suggesting a redistribution of martensitic variants induced by the load applied during the transformation. Moreover, with increasing load the amount of deformation associated with the phase transformation was also found to increase gradually.

According to the variations in the diffraction patterns, the uniaxial compressive load applied significantly influences the martensitic transformation thermodynamics, resulting in increased transformation temperatures. The shifts of transformation temperatures under uniaxial load σ can be well explained by the Clausius-Clapeyron equation [4].

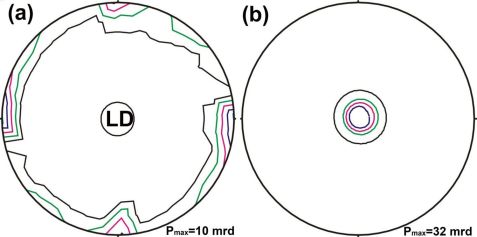

Texture evolution

Since the easy magnetization axis is an important parameter that accounts for the magnetocrystalline anisotropy in Ni-Mn-Ga alloys, we shall focus on the orientation distribution of the easy magnetization axis of 7M martensite (i.e. <010>7M). Fig. 3a and Fig. 3b display the (020)7M complete pole figures of the samples without and with the cyclic TMT, respectively. It can be seen that in the initial state (Fig. 3a), the <010>7M directions of 7M martensite tend to be perpendicular or parallel to the SD. After three cycles of treatment (Fig. 3b), the <010>7M directions become almost parallel to the LD (which is also the SD). Notably, a strong <010>7M preferential orientation along the LD was induced by the external compression during martensitic transformation [4].

Furthermore, magnetization measurements show that the sample after cyclic TMT makes it much easier to reach saturation, suggesting the enhancement of magnetocrystalline anisotropy induced by the external compression during martensitic transformation.

In summary, direct experimental evidence was obtained on the redistribution of martensitic variants, triggered by uniaxial compression during martensitic transformation. The cyclic TMT resulted in large unidirectional lattice strains for the martensitic transformation and hence significant changes in the martensite microstructure. The 7M martensite plates formed with a strong <010>7M preferential crystallographic orientation along the loading axis, leading to an enhancement of the magnetocrystalline anisotropy. The present investigations may provide fundamental information on variant selection subjected to external stress field and the necessary guidelines for microstructure optimization of polycrystalline Ni-Mn-Ga alloys through external field training.

References:

[1] H. G. Brokmeier et al., Nucl. Instr. Meth. A 642, 87 (2011).

[2] M. Hoelzel et al., Nucl. Instr. Meth. A 711, 101 (2013).

[3] Z. B. Li, et al., J. Appl. Crystallogr. 43, 617 (2010).

[4] Z. B. Li, et al., Appl. Phys. Lett. 105, 021907 (2014).

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: