MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

Radiometric investigation of water vapour movement in wood based composites

K. Solbrig1, K. Frühwald1, J. B. Ressel2, B. Schillinger3, and M. Schulz3

1Laboratory for Timber Engineering, Products and Production, Ostwestfalen-Lippe University of Applied Sciences, Lemgo, Germany

2Department of Wood Science, University of Hamburg, Hamburg, Germany

3Heinz Maier-Leibnitz Zentrum (MLZ), Technische Universität München, Garching, Germany

Many physical interrelations within the wood particle mat during the hot pressing process of wood based composites (WBC) are based on assumptions. Neutron radiography is able to distinguish between wood and moisture (X-ray lacks sufficient contrast), thereby providing specific information on dynamic processes where only models exist. Experiments at ANTARES employing a special setup evaluate the applicability of NR for in-situ investigations on vapour movement during hot pressing. The results visualise and quantify vapour movement depending on varying process parameters.

The hot pressing process of wood based composites

WBC are industrially produced panels made of resin-blended wood particles (e. g. wood fibres with 8 – 14 % resin content). The formed particle mats are densified and cured in hot presses. Several physical models (cf. [1]) exist for mechanisms such heat and mass transfer that occur during the hot pressing of wood particle mats. More generally, a not as yet visualised concept of a wave-front-like vapour movement exists. A continuous X-ray radiometric investigation of the hot pressing process was carried out by [2]. Standard X-ray methods lacks sufficient contrast between water vapour (H2O) and dry wood matter (mainly H, C, N, O). On the contrary, neutron radiography (NR) is very sensitive even to small amounts of water vapour due to the considerably higher effective cross section of hydrogen compared to the other elements present. Time-resolved NR allows comprehensive measurements of the actual vapour movement over the total cross section of the WBC panel, in contrast to hitherto used estimations with single probes of temperature and vapour pressure.

Emulation of the heat and mass transfer

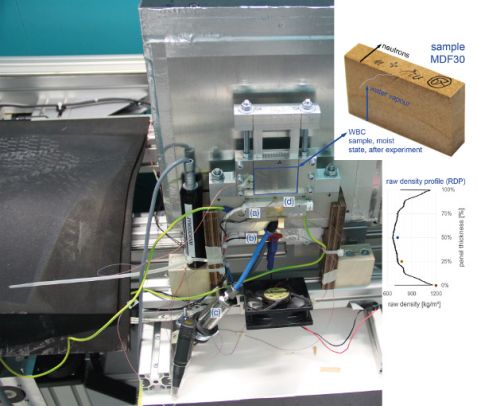

The experiments presented serve as preliminary tests for the in-situ investigation of the hot pressing process. To this end, an appropriate, simple setup was designed to generate heat and mass transfer (fig. 1). The predominant distinctive vapour movement inside the sample was varied within a practice-oriented range of temperature and pressure settings. NR measurements were carried out by means of a set of samples systematically covering a well-defined range of raw density profiles over the panel thickness and different initial material moisture contents. The amount of water for vapour generation was individually calculated per sample type to obtain reasonable specimen moisture conditions. Despite the stagnation of the emulated vapour movement after 60 – 180 s from the initial vapour generation, the process and capturing time was chosen up to 660 s (incl. 120 s of pre-heating) to obtain a desiccation within the panel surface, which typically occurs during hot pressing.

Measurements at ANTARES

The NR measurements were carried out using an L/D of 280 (2.1 ∙ 108 n cm-2 s-1), 2 × 2 binning, an exposure time of 0.25 s at a repetition rate of 1.61 s restricted by the read out time. The pixel size was 146.5 µm. Prospectively faster and higher resolved NR imaging will be available after full completion of ANTARES.

In-situ investigation of water vapour movement

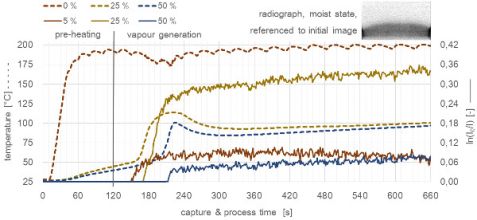

One sample was selected (fig. 1, MDF30) for exemplary presentation of the NR results in figure 2 with data of representative positions along the panel thickness [%]. To evaluate the vapour movement, i.e. the water content per time step at a certain position, the time-resolved NR images were referenced to NR images of the initial dry state (fig. 2, insert). The logarithm of this reciprocal pixel value ln(I0/I) [-] corresponds to the relative water content (solid lines). A delayed sharp increase in the water content observed by NR proves the wave-front-like vapour movement, which is also confirmed in the correspondingly monitored temperature (dashed lines). The time delay of the increase correlates to the thickness position. A kind of vapour saturation is obvious at position 25 %. The vapour wave front does not move along the total cross section but, rather, stops at around 25 % panel thickness where the raw density decreases (fig. 1, RDP). The density decrease leads to higher permeability of the densified wood particles and a respective vapour pressure decrease resulting in a precipitation of vapour in this section. A near-surface desiccation is indicated by the falling slope of the 5 % chart (starting at 480 s).

The estimated wave-front-like vapour movement characteristic becomes clear from this brief data evaluation. Despite the preliminary nature of these experiments, the applicability of NR to quantitative in-situ investigations of the hot pressing process is shown and the results provide valuable information about mechanisms within the wood particle mat during hot pressing. This enhanced knowledge offers fundamental approaches to further improve the production of WBC and their material properties.

References:

[1] P. E. Humphrey, In: Proc. Int. Cellucon Conf., Bangor (1994).

[2] M. Gruchot, Diss. Uni Hamburg (2009)

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: