MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

Macroscopic and microscopic residual stresses in friction stir welded metal matrix composites

X. X. Zhang1, D. R. Ni1, B. L. Xiao1, H. Andrä2, W. M. Gan3, M. Hofmann4, Z. Y. Ma1

1 Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences, Shenyang, China

2 Fraunhofer Institute for Industrial Mathematics, Kaiserslautern, Germany

3 German Engineering Materials Science Centre (GEMS) at MLZ, Helmholtz-Zentrum Geesthacht GmbH, Garching, Germany

4 Heinz Maier-Leibnitz Zentrum (MLZ), Technische Universität München, Garching, Germany

A new experimental method to determine the macroscopic and microscopic residual stresses in metal matrix composite welds via neutron diffraction has been developed. Friction stir welded 17 vol.% SiCp/2009Al-T4 composite plates were studied as an example. We found that, surprisingly, the profiles of longitudinal (L), transverse (T) and normal (N) components of the total residual stress in the reinforcement are entirely different from those in the matrix. The total residual stress profiles in the matrix are dominated by the macroscopic stress, whereas in the reinforcement the elastic mismatch (microscopic) residual stress prevails. It also turned out that it is better to use the absolute unstrained lattice parameter of SiC powder and the stress equilibrium condition to accurately calculate the thermal and plastic misfit residual stresses in the matrix.

Residual stress in metal matrix composite welds

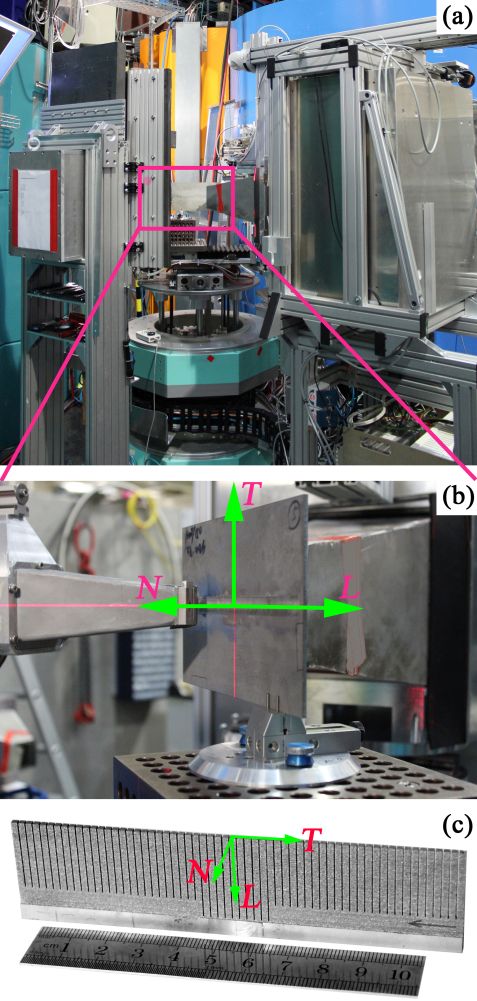

Figure 1: Experimental setup at STRESS-SPEC (a), showing the welded plate (b) and the comb sample (c).

Metal matrix composites (MMCs) are widely used in advanced industries because of their outstanding properties. However, the poor weldability of MMCs is one of the major factors that limit the widespread application of MMCs. Friction stir welding (FSW) is considered to be a promising technique for joining MMCs. As with other welding processes, residual stresses are generated after FSW. Residual stress in the welds is a crucial issue because it significantly affects the weld properties, such as plastic collapse, fatigue properties and stress corrosion [1], which makes it an essential property that engineers need to assess quantitatively in order to predict the structural integrity of welded components. However, determining residual stresses in MMC welds is quite difficult. On the one hand, residual stresses in MMCs include both considerable microscopic (originating from the elastic mismatch, thermal and plastic misfit between matrix and reinforcement) and macroscopic stresses [2]. On the other hand, the measurement of the unstrained reference lattice parameters for the metal matrix in MMC welds is especially difficult [2, 3], as lattice parameters vary with the phase transition in the matrix after thermal exposure during welding.

In the past, neutron/synchrotron X-ray diffraction and the Eshelby model were combined to characterize multiscale residual stresses in MMCs. Nonetheless, this method suffers from complexity in calculation, poor applicability and poor accuracy. Our study proposes a new and reliable experimental method to determine multiscale residual stresses in MMC welds via neutron diffraction. Using this method, multiscale residual stresses in FSW SiCp/2009Al-T4 welds have been characterized.

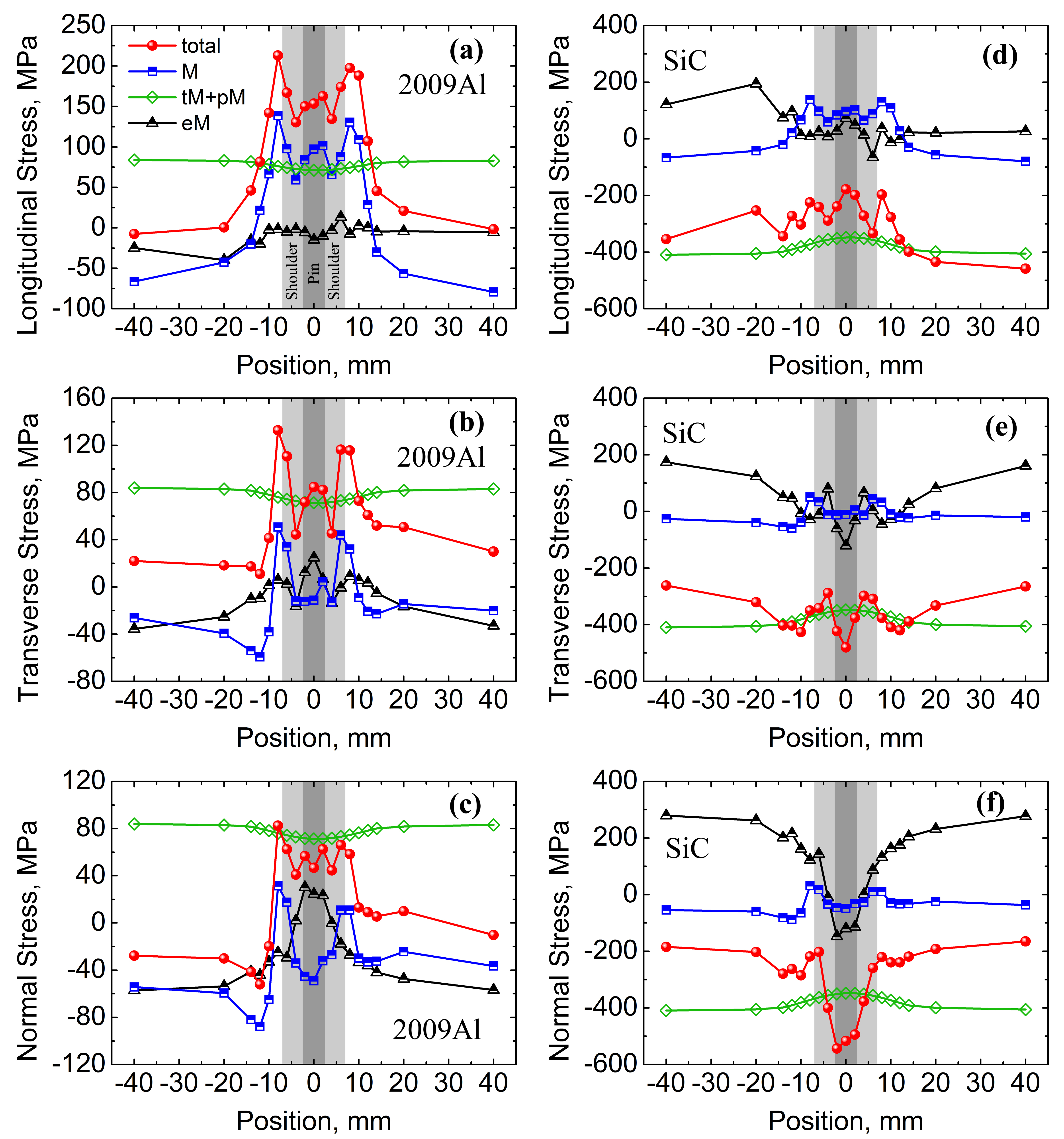

Figure 2: The profiles of the macroscopic (M), elastic mismatch (eM), thermal plus plastic misfit (tM+pM), and total residual stresses in both the Al matrix and SiC reinforcements across the weld. The rotation rate is 1500 rpm.

Separation of multiscale residual stresses

First, the phase specific residual strains are measured. To do this, the weld sample, together with a comb sample of the weld and the reinforcement (SiC) powder sample are measured using neutron diffraction at STRESS-SPEC (Fig. 1, [4]). The residual strains are then mapped to multiscale residual stresses via a new proposed calculation method based on the Bragg equation and the stress equilibrium condition [4]. In the course of this procedure, it was found that the calculation of the thermal plus plastic misfit residual stresses in the matrix of the MMC welds is much more accurate when using the absolute unstrained lattice parameter of the SiC powder rather than the unreinforced alloy sample.

The resulting phase specific multiscale residual stresses in the FSW SiCp/2009Al-T4 are plotted separately in Fig. 2. It shows that the profiles and total variations of the L, T and N components of the total residual stress are determined by those of the macroscopic residual stress in the matrix. The elastic mismatch residual stress has a comparatively minor effect on the total residual stress in the matrix. In contrast, the total residual stress profiles in the reinforcement are totally different from those in the matrix. For instance, the L component of the total residual stress in the matrix in particular has a typical M-shape, whereas that in the reinforcement has three peaks. The N component of the total residual stress in the matrix has an M-shape, whereas that in the reinforcement has a V-shape. Finally, in the reinforcement, the total residual stress is dominated by that of the elastic mismatch residual stress.

Effects of rotation rate on the residual stress

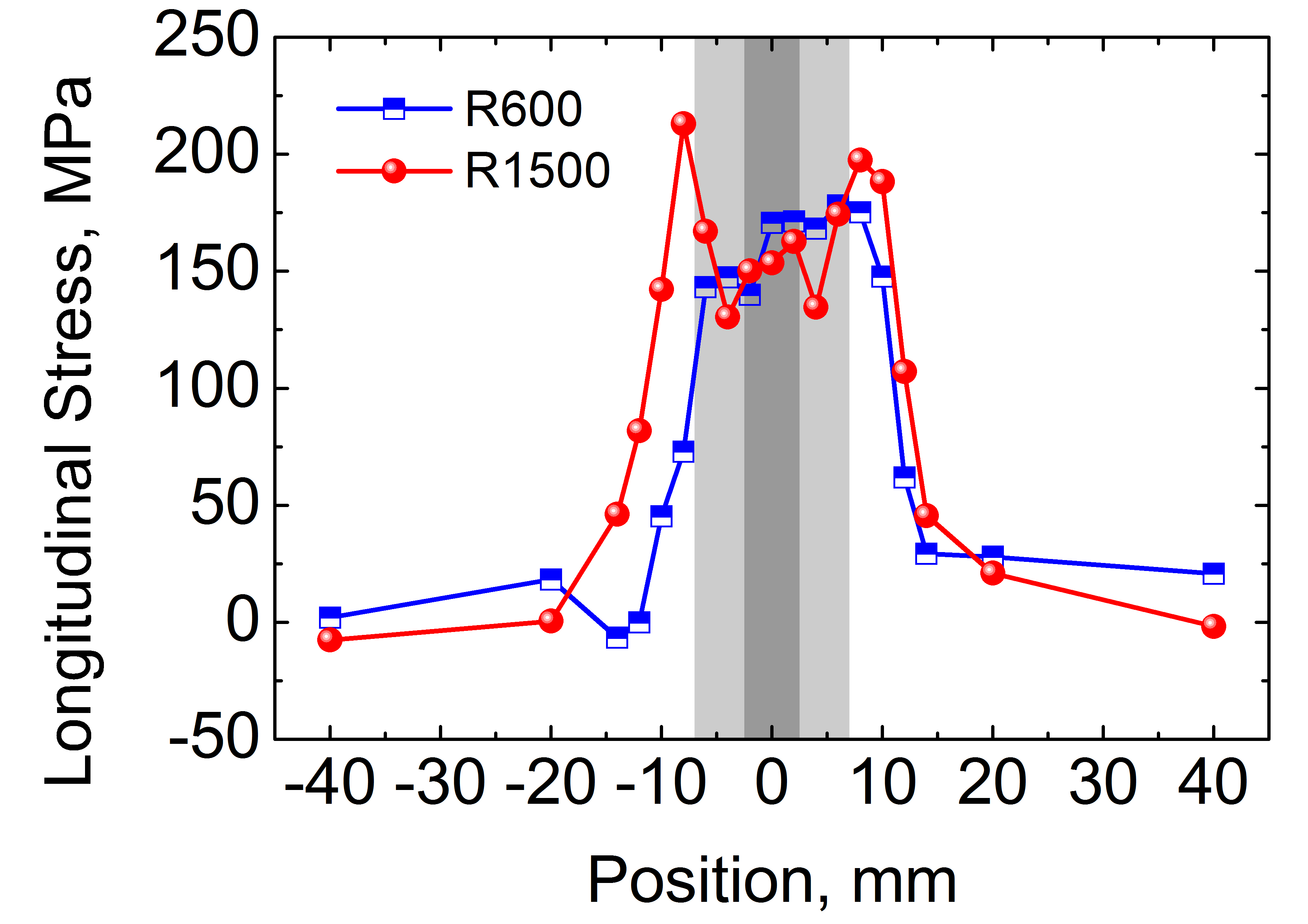

The new method was applied to quantitatively determine the effects of different welding conditions on residual stresses in MMCs. Fig. 3 compares the total residual stress of the metal matrix between R600 (rotation rate 600 rpm) and R1500 (rotation rate 1500 rpm). It indicates that raising the rotation rate has a small effect on the basic profiles of the total residual stress, but increases the width of the profiles, which agrees with previous investigations [5]. The maximum total residual stress in the matrix of R1500 is about 213 MPa, reaching up to ~ 69% of the yield strength of the 2009Al-T4 alloy, while in the reinforcement the stress with the maximum magnitude is about -550 MPa.

Figure 3: Comparison of the L component of the total residual stress for R600 (rotation rate 600 rpm) and R1500 (rotation rate 1500 rpm) in the Al matrix.

References:

[1] P. J. Withers, Rep. Prog. Phys. 70, 2211 (2007).

[2] M. E. Fitzpatrick et al., Acta Mater. 45, 4867 (1997).

[3] P. J. Withers et al., J. Appl. Crystallogr. 40, 891 (2007).

[4] X. X. Zhang et al., Acta Mater. 87, 161 (2015).

[5] A. P. Reynolds et al., Scr. Mater. 48, 1289 (2003).

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: