MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

20.10.2021

Testing test methods

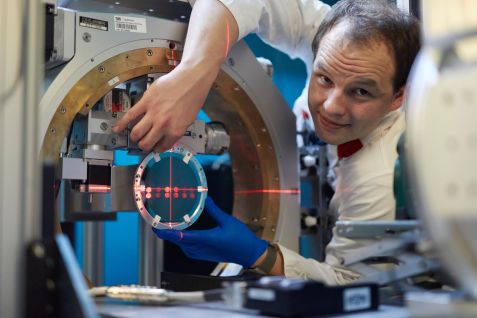

PhD student Tobias Neuwirth installs the setup for the experiments on the ANTARES instrument. © Bernhard Ludewig / FRM II, TUM

In the manufacturing of turbines conventional processes often reach their limits. Therefore, additive manufacturing is increasingly used to produce complex, curved components with intricate structures. A research team from the Technical University of Munich (TUM) has now examined common methods used to locate defects inside components. In their investigation neutron grating interferometry, performed at the Heinz Maier-Leibnitz research neutron source (FRM II), achieved the best defect detection.

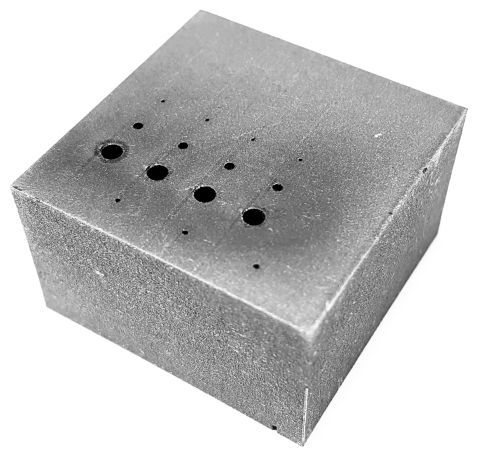

Laser beam melting is a common 3D printing process for turbine blades with internal cooling channels. During this process, a laser melts a thin layer of metal powder in predefined areas. Layer by layer, the component forms in a bed of powder. Similar to an archeological excavation, the component is then exposed and the remaining powder can be reused for the next printing process.

However, process instabilities can lead to defects and reduce the strength of the component. Typical defects are pores and cracks. Even partial or total separation of individual layers can occur.

For safety-critical components such as turbine blades, such defects can have serious consequences. “That is why we need to inspect critical components after the manufacturing process – non-destructively, of course,” explains Cara Kolb from the Institute for Machine Tools and Industrial Management at TUM.

A look inside

For their experiments, the researchers produced test specimens with defects of different size and depth and then attempted their detection using non-destructive testing methods. This involved active infrared thermography (aIRT), ultrasonic testing (UT), X-ray computed tomography (CT) and neutron grating interferometry (nGI).

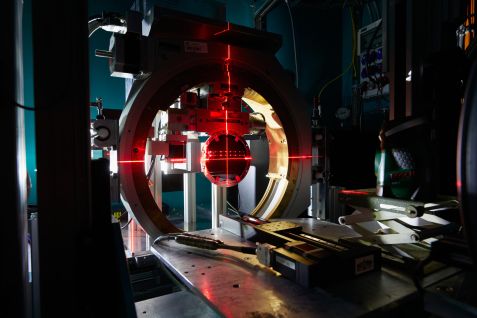

At the research neutron source doctoral student Tobias Neuwirth conducted the experiments at the ANTARES instrument. “We investigate components using neutron grating interferometry, observing the scattering and absorption of neutrons in a spatially resolved manner. Changes in these properties give us information about the type and size of the defects,” he explains.

With the help of lasers, the researchers precisely align the neutron grating interferometer and bring it into the correct position. © Bernhard Ludewig / FRM II, TUM

Deeper penetration and better resolution with neutrons

Each of the methods tested has both potential and challenges. Neutron grating interferometry is complex and more expensive than the other test methods investigated, but of all the methods, it detected the most and the smallest defects.

“Neutrons can penetrate deep into the material and resolve the internal component structure with high resolution. They are particularly suited to nickel-based alloys, which are enormously important for the additive manufacturing of structural components in aerospace,” concludes Cara Kolb.

Research into testing procedures that non-destructively assure the quality of 3D-printed components is very important: Such procedures reveal the likelihood of a component failure during operation. They are also ever more important as additive manufacturing in aircraft and cars, for example, increases.

Publication:

C. G. Kolb, K. Zier, J.-C. Grager, A. Bachmann, T. Neuwirth, S. Schmid, M. Haag, M. Axtner, F. Bayerlein, C. U. Grosse, M. F. Zaeh

An investigation on the suitability of modern nondestructive testing methods for the inspection of specimens manufactured by laser powder bed fusion

SN Appl. Sci., 3, 713 (2021) – DOI: https://doi.org/10.1007/s42452-021-04685-3

More information

The experiments to investigate the ability of neutrons to detect defects were conducted at FRM II using the ANTARES facility at the Heinz Maier-Leibnitz Zentrum (MLZ) center. CT scans were provided by FIT AG, Lupburg.

Contact:

Prof. Dr.-Ing. Michael Zäh

Technical University of Munich

Institute for Machine Tools and Industrial Management

Tel.: +49 89 289 15502

E-mail: michael.zaeh@iwb.tum.de

Tobias Neuwirth

Technical University of Munich

Heinz Maier-Leibnitz Zentrums (MLZ)

Instrument ANTARES

Tel.: +49 89 289 11754

E-mail: Tobias.Neuwirth@frm2.tum.de

Related News

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: