MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

14.03.2023

Super methods for superalloys

The newly developed superalloy VDM® Alloy 780 withstands temperatures of up to 750°C and endures enormous forces with ease. Such materials are real superheroes among alloys. And just like human superheroes, they have very special laboratories and methods with which they can improve their strength. Neutrons and X-rays are an indispensable part of this research.

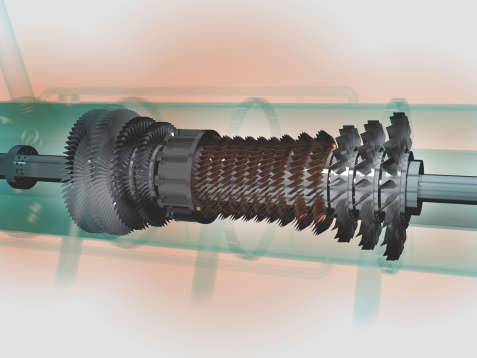

Superalloys from VDM are used, for example, in gas turbines, where they have to withstand high temperatures and forces. Optimized superalloys can improve the durability and efficiency of such turbines. © FRM II

Superalloys owe their stability, among other things, to their internal structure, i.e. the way in which the atomic constituents arrange themselves. They form a regular crystal lattice, the so-called γ-matrix, which forms the basic structure of the alloy. In addition, various substructures and other elements are embedded to increase the stability and heat resistance of the alloy. One of these processes is the generation of another phase, the so-called γ’-phase. It consists of single-crystalline precipitates arranged within the alloy and embedded in the γ-matrix. These precipitates, typically on the order of nanometers, are formed when the alloy undergoes an appropriate temperature treatment. They increase the mechanical stability of the alloy because they act as barriers to atomic rearrangements. The VDM® Alloy 780 alloy produced by the metallic materials company VDM Metals also owes its stability to this principle, and promises operating temperatures of up to 750°C. To better understand its properties, scientists from the BMBF HiMat project have studied the alloy with neutrons and X-rays.

Dr. Cecilia Solis at the dilatometer in the MLZ Materials Science Laboratory. © Bernhard Ludewig, FRM II / TUM

Precipitated and crystallized: The origin story of the γ’-phase

Dr. Cecilia Solis, a scientist at MLZ, investigated the question of exactly how the γ’-phase forms and evolves. She and her colleagues investigated the alloy VDM® Alloy 780, provided by the company VDM Metals, by preparing the alloy in three different ways: Once without and once with a γ’-phase. A third was treated such that the γ’-phase was just beginning to precipitate and was thus only weakly present.

They used small-angle neutron scattering (SANS) on the SANS-1 instrument at the Heinz Maier-Leibnitz Zentrum and TOF neutron diffraction on the GEM instrument at the ISIS Neutron and Muon Source in the UK for an in-situ measurement, while the samples were kept at typical operating temperatures of 750°C. The goal of the measurements was to better understand exactly how the precipitates are formed and how to affect the size and volume fraction of the precipitates. “The big advantage of the SANS method is that we can perform the measurement in a very short time. This makes it perfect for in-situ measurements, where we want to study the evolution of the γ’-phase over time, i.e., to understand the kinetics,” says Cecilia Solis.

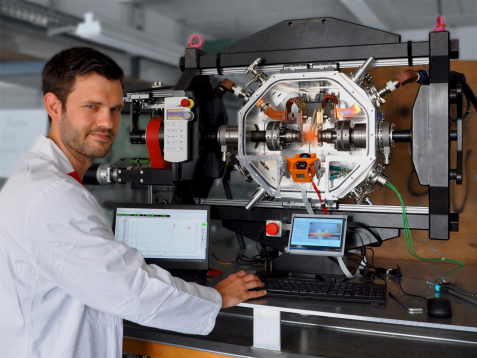

Dr. Frank Kümmel at a specially developed testing machine for testing superalloys. © Reiner Müller, FRM II/TUM

How to defeat a superalloy?

But what happens to the γ’-phase at temperatures well above the maximum operating temperature of the superalloy? Dr. Frank Kümmel, until recently a scientist at MLZ, and his colleague Dr. Massimo Fritton have also used X-ray and synchrotron radiation to study the VDM® Alloy 780 alloy in order to understand its stability and longevity. The two methods differ essentially in their energy and thus in their depth of penetration. The former have energies that are conveniently generated using laboratory instruments, but can only penetrate a few micrometers deep into the alloy. Synchrotron beams, on the other hand, are highly focused beams with many times the energy of conventional X-rays. They can thus penetrate several millimeters into the sample.

Fully stable below 750°C

The synchrotrons are generated at large research facilities, such as the German Electron Synchrotron in Hamburg. Frank Kümmel and Massimo Fritton also made their measurements at the PETRA III synchrotron there. “With both methods, investigations are possible both on the surface and inside the sample, and by comparing them we can distinguish surface effects from effects inside the sample,” explains Frank Kümmel. With the combined measurements, the two scientists were able to show that the γ’-phase is retained throughout the alloy at temperatures below 750°C and thus exhibits full stability. Only at 800°C does it begin to dissolve and the γ’-forming elements are absorbed into the γ-phase, causing it to expand. They also observe this effect on the surface of the alloy, but there it is not as pronounced, which could be due to oxidation effects.

“These new findings are of great value for materials science but also for industry to further optimize the alloy,” says Ralph Gilles, coordinator of the BMBF HiMat project, where the two alloy investigations were conducted. After all, the superalloys from VDM Metals are used for example in gas turbines, where they have to withstand extreme temperatures, among other things. This could allow turbines to run more efficiently in the future. “Neutrons are an indispensable tool for such investigations because they can penetrate deeper into the sample than conventional X-rays, for example, and measure a much larger volume non-destructively and in-situ”, he explains.

Original publications:

- C. Solís, A. Kirchmayer, I. da Silva, F. Kümmel, S. Mühlbauer, P. Beran, B. Gehrmann, M. Hafez Haghighat, S. Neumeier, R. Gilles. Monitoring the precipitation of the hardening phase in the new VDM® Alloy 780 by in-situ high-temperature small-angle neutron scattering, neutron diffraction and complementary microscopy techniques

Journal of Alloys and Compounds (2022), 928

- F. Kümmel, M. Fritton, C. Solís, A. Kriele, A. Stark, R. Gilles. Near-Surface and Bulk Dissolution Behavior of γ′ Precipitates in Nickel-Based VDM® Alloy 780 Studied with In-Situ Lab-Source and Synchrotron X-ray Diffraction

Metals (2022), 12, 1067

Further information:

The project “HiMat” (Project number 05K19WO7) is supported by the Federal Ministry of Education and Research (BMNF).

Related News

-

24.08.2017

Hot tests with neutrons

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: