MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

08.02.2022

Neutrons explore more efficient hydrogen storage systems

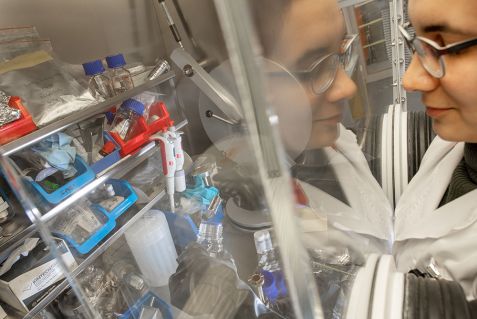

Neslihan Aslan prepares the sample in powder form for analysis on the TOFTOF instrument. The powder is highly sensitive, so she must handle it under low-oxygen conditions in a glove box. © A. Heddergott / TUM

Hydrogen plays an important role in the transition to a sustainable energy infrastructure. It is particularly promising as a potential energy storage medium because of its flexible applications, for example in electromobility or in the steel industry. Nevertheless, the technology still faces major obstacles, especially in terms of energy efficiency and high costs. Intensive research goes into developing solutions and the neutrons from FRM II are contributing to this effort.

The basic principle of these technologies is simple: hydrogen reacts with oxygen to form water, releasing energy in the process. Conversely, it costs energy to produce the hydrogen. If one manages to store it, it can be brought to reaction later in order to release the stored energy into electricity. The problem is that pure hydrogen can only be stored at very high pressure and low temperatures, otherwise it could escape through almost any vessel wall. This is not practical for many applications, starting with transportation. For this reason, people have long been searching for solids that can chemically bind the hydrogen.

It’s the mixture that counts – but what happens microscopically?

The aluminum cylinder with the powder sample is attached to the specimen before it goes to the TOFTOF instrument for measurement. Wiebke Lohstroh (in the background), head of the TOFTOF instrument, supports her PhD student during the measurements. © A. Heddergott / TUM

These solids should be able to store hydrogen in high quantities, and the chemical reactions to produce or release hydrogen should be fast and efficient. One type of solid has stood out in particular: compounds of light alkali and alkaline earth metals such as lithium or magnesium, and hydrogen-containing molecules. The key is the right mixture of several of these compounds in the hydrogen storage system: By cleverly combining them, it is possible to control via the applied temperature and pressure whether hydrogen is absorbed or released.

Neslihan Aslan is a PhD student at the German Engineering Materials Centre (GEMS) of the Helmholtz Centre Hereon at MLZ and conducts research on hydrogen storage systems of this kind. Together with colleagues from the Institutes of Hydrogen Technology and Materials Physics at Hereon and MLZ, she has taken a closer look at the compound Li4(BH4)(NH2)3, which is formed as a product in one of these compounds after hydrogen is released. While it is already known that this solid is a good hydrogen storage material, it is not understood why this is so at the microscopic level. This includes the crystal structure itself, as well as the dynamic processes such as diffusion and rotation of the hydrogen atoms within it.

Neutrons reveal high mobility of hydrogen

Neslihan Aslan studied the crystal structure and its stability up to its melting point using synchrotron radiation at the German Electron Synchrotron (DESY) together with Claudio Pistidda from the Institute of Hydrogen Technology. For the dynamical processes she turned to the TOFTOF instrument at MLZ for quasielastic neutron scattering (QENS). “This measurement at such a precision is not possible with any other method, because neutrons are ideal for studying hydrogen, and additionally they can resolve events in time and thus make them measurable,” explains Neslihan Aslan.

Her supervisor at GEMS, Sebastian Busch, is also very satisfied: “The results look very good, and we were also able to see the high mobility of the hydrogen within the solid,” he says. This is important for a fast reaction. The next step is to study the entire solid with measurements during the charging and discharging process to investigate the interaction of the individual components. Here, too, neutrons can provide a deep insight.

Original publication:

Neslihan Aslan, Gökhan Gizer, Claudio Pistidda, Martin Dornheim, Martin Müller, Sebastian Busch, Wiebke Lohstroh. High Hydrogen Mobility in an Amide–Borohydride Compound Studied by Quasielastic Neutron Scattering. Advanced Engineering Materials/ Volume 23/ Issue 11. DOI: 10.1002/adem.202100620

Related News

-

12.06.2020

Hydrogen – but efficiently

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: