MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

06.02.2023

Neutron beam for better batteries

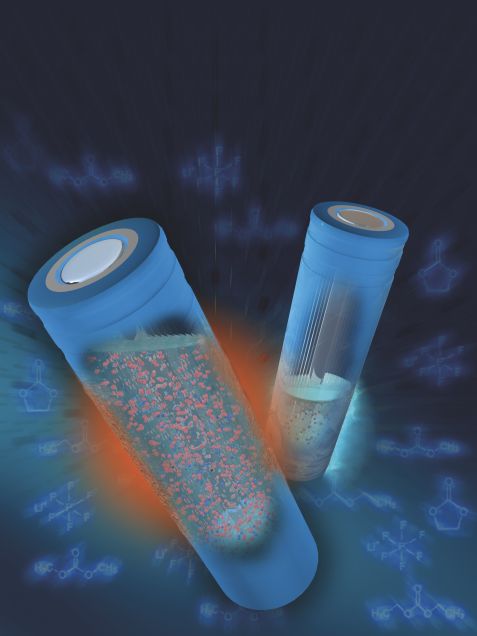

With new insights into the interior of lithium-ion batteries, a team of scientists led by Dr Anatoliy Senyshyn and Dominik Petz has succeeded in taking another step towards longer-lasting batteries. Neutron scattering at MLZ’s STRESS-SPEC instrument and further measurements showed a correlation between higher temperature development of the battery and its age.

In order to store renewable energy, the use of rechargeable batteries will become even more important in the future. But unfortunately, the storage capacity of even the best lithium-ion batteries decreases over their lifetime.

Researchers at the Heinz Maier-Leibnitz Center, together with colleagues from the universities of Münster and Stuttgart, the Lawrence Berkeley National Laboratory in the U.S. and Dalhousie University in Halifax, Canada, have now found another clue as to how we might extend the useful life in the future by looking inside the batteries.

A look inside the accumulator

Neutrons penetrate the interior of accumulators non-destructively and almost without attenuation: they first interact with the electrode materials inside. When they collide with the elementary building blocks of the accumulators, they do not change their internal structure. Nevertheless, the deflection of the neutrons is large enough to conclude the distribution of the stored lithium in the cells. The researchers thus achieved an experimental resolution of a few millimeters.

The team led by Dr Anatoliy Senyshyn, instrument scientist at MLZ, and Dominik Petz, PhD student at the Technical University of Munich at MLZ, used the STRESS-SPEC materials research diffractometer with the assistance of instrument scientist Dr Michael Hofmann to look inside a series of conventional cylindrical 18650 lithium-ion batteries, some of which had undergone over 1000 charge cycles.

Lost lithium

But what is the exciting thing about the distribution of lithium in the cell? The way lithium-ion batteries work offers some insight here. During the discharge process, an electron is released from the lithium atoms and migrates through the device to be supplied with electricity. At the same time, the lithium-ion diffuses inside the cell from the anode to the cathode. There, the electrons and lithium ions reconnect inside the cathode and are available – at least theoretically – for the reverse process during charging.

However, if the battery now loses active lithium, it loses capacity. The loss of mobile atoms can be explained by reactions with the electrolyte in which they move.

The older the warmer

The researchers found that the loss of the electrolyte component LiPF6 and the available lithium atoms are directly related. This leads them to believe that artificially adding fresh lithium could keep the concentration constant for longer and thus increase the cell’s lifetime. This approach could pave the way toward much more powerful batteries.

They also found a direct correlation between the surface temperature of battery cells and their ageing state. Older batteries showed a significantly greater temperature increase due to increased internal resistance at the same charging or discharging current. However, the surface temperature was not completely uniformly distributed. Dominik Petz and his colleagues now want to further investigate the relationship between temperature development and the ageing state of the batteries.

Original publication:

D. Petz, V. Baran, C. Peschel, M. Winter, S. Nowak, M. Hofmann, R. Kostecki, R. Niewa, M. Bauer, P. Müller-Buschbaum, A. Senyshyn

Aging-Driven Composition and Distribution Changes of Electrolyte and Graphite Anode in 18650-Type Li-Ion Batteries

Advanced Energy Materials, 2201652 (2022)

10.1002/aenm.202201652

Further information:

The project was developed with the participation of the Deutsches Elektronen Synchrotron (DESY), the Münster Electrochemical Energy Technology (MEET) at the Westfalian Wilhelms-University Münster, the Energy Storage and Distributed Resources Division at Lawrence Berkeley National Laboratory (USA), the Institute of Inorganic Chemistry at the University of Stuttgart and the Department of Physics and Atmospheric Science at Dalhousie University in Halifax (CA).

The work was supported by the German Federal Ministry of Education and Research and the Bavarian-Californian Center for Higher Education.

Contact:

Dr. Anatoliy Senyshyn

Research Neutron Source Heinz Maier-Leibnitz (FRM II) and Heinz Maier-Leibnitz Zentrum (MLZ)

SPODI instrument

Phone: +49 89 289 14316

E-Mail: anatoliy.senyshyn@frm2.tum.de

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: