MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

10.05.2022

Life after the cycle: How fuel elements contribute to research for final repositories

The final stage for each fuel element at the Research Neutron Source Heinz Maier-Leibnitz (FRM II) is the storage pool. Here it waits several years before its onward transport. Taking advantage of this, one research team is using the remaining energy for valuable studies. For instance, they are examining salt crystals for the final disposal of radioactive waste – and dreaming of applications on a grander scale.

The life cycle of a FRM II fuel element begins in France: here, the manufacturer rolls thin plates from fresh uranium silicon powder and presses them into a so-called aluminum sandwich. 113 such plates result in a fuel element in the shape of a hollow cylinder. The fresh fuel element is transported to Garching by special vehicles.

The active life of the fuel element then begins at the research neutron source. For 60 days, it provides neutrons for researchers to use. From the origin of the universe to the improvement of mRNA-based drugs: the range of applications for neutrons is large.

Spent but not out of service

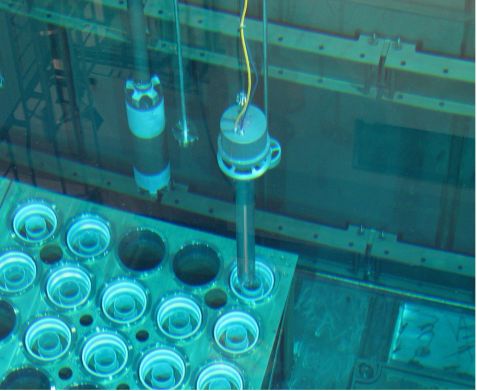

After a full cycle, the fuel element ends up in the decay pool, where water contains the remaining radiation. Here, the spent fuel element is stored in a rack for at least 6.5 years before it can be transported onto the interim storage facility.

Sophie Bulla (left), systems engineer in charge of the irradiation facilities, Dr. Xiaosong Li (back), involved in the construction of the facility, and irradiation operator Jens Molch (right) at the gamma irradiation facility. © MLZ

But that spent fuel element also serves further research purposes, because it continues to emit energy in the form of gamma radiation. Therefore, in 2009 researchers at FRM II built a gamma irradiation facility together with scientists from RWTH Aachen University. This was inspected by TÜV in 2014 and put into operation.

The facility essentially consists of an insulated capsule that provides space for samples up to 70 cm long and 7.6 cm in diameter. The capsule is lowered into the cavity in the center of the fuel assembly. Since the radiation is not homogeneously distributed inside, researchers can regulate the sample’s dose by its positioning alone. They can also adjust the temperature in the capsule between 30 and 150°C as needed.

Research on final disposal sites

The gamma irradiation facility was developed as part of a project by Prof. Dr. Janos Urai of RWTH Aachen University, supported by the Deutsche Forschungsgemeinschaft (DFG). The main objective was to study microstructures in rock salt crystals as they occur in salt domes

Salt domes are an important candidate in the search for a geological repository for radioactive waste and are already in use for chemical waste. “A detailed understanding of the flow properties and deformation processes of rock salt is crucial for predicting the stability of such repositories in the long-term perspective,” explains physicist Dr. Vladimir Hutanu, a member of the Department of Radiation and Sources at FRM II.

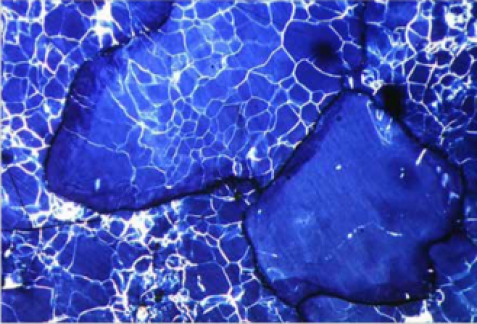

With the help of irradiation experiments, scientists at RWTH Aachen University were finally able to explain why laboratory studies on the recrystallization of salt could not be directly transferred to the dynamics in the salt dome: It is due to the water that is contained as brine in natural salt minerals and collects in pores and at grain boundaries. This microstructure largely determines the stability of the material, but is not visible under the microscope.

After irradiation with high-energy gamma rays, small defects known as color centers form inside the mineral. The transparent salt thus turns blue, but trapped water does not. The researchers can then see the microstructure, the hidden water in the salt, under the microscope.

More ideas welcome

“Our facility is unique and special,” says Hutanu, listing other possible applications. For example, investigating the stability of building materials or the elasticity of polymers, irradiating biological cells to detect mutations in the genome, sterilizing medical implants, or testing the radiation resistance of electronic components.

There is room for a total of 50 fuel assemblies in the decay pool, and so far there is only one gamma irradiation facility. But Hutanu has ambitious plans: “I could imagine us using more such irradiation facilities and several fuel elements simultaneously in the future.” Florian Jeschke, deputy technical director of FRM II, also affirms, “We are always interested in working with new potential users of this facility.”

Contact:

Dr. Vladimir Hutanu

Vladimir.hutanu@frm2.tum.de

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: