MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

17.08.2020

Improved welding process for turbine parts

Welding a pipeline. The researchers performed a precise analysis of the joint of welded seams. © rominaluchetta/Pixabay

Scientists at the Heinz Maier-Leibnitz Zentrum (MLZ) use imaging techniques with neutrons to study specially bonded steel components. With their results they can improve the welding process for oil and gas pipelines and turbines.

The “transient liquid-phase bonding” (TLPB) process is used for joining metallic systems where standard welding methods cannot be used. For example in the repair of gas pipelines. By using special materials, the TLPB process achieves very good mechanical properties.

Researchers at MLZ have now taken a closer look at this type of welded joint. With their method they can non-destructively test the quality of TLPB joints. In doing so, they discover harmful inclusions at the fusion joint. This is particularly important for the oil and gas industry, where the TLPB method is used particularly often. It is also used in the manufacture of turbine blades in jet engines.

Neutrons make the joining seam visible

Scientists Dr. Nicolás Di Luozzo and Dr. Marcelo Fontana from the Universidad de Buenos Aires (UBA) together with MLZ scientist Dr. Michael Schulz (Technical University Munich) have investigated TLP-bonded steel components with boron-alloyed foils. For this purpose they used neutron radiography and tomography at the instrument ANTARES.

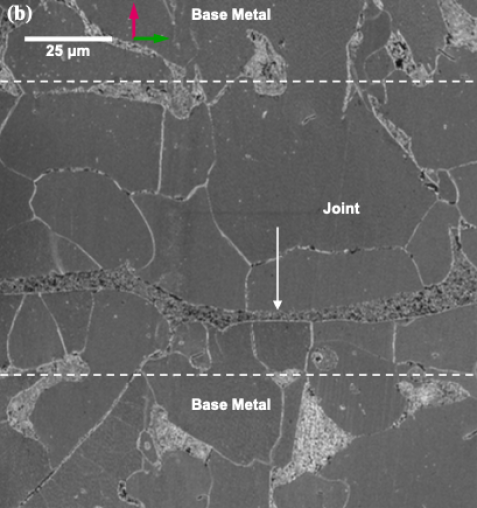

The neutrons make the “seam” between the metal parts, the microstructure of the compound and the subsequent base metal, visible. “With existing microscopic methods it is not possible to quantify the boron concentrations in a steel matrix,” Di Luozzo explains, “quite contrary to neutron radiography. The spatial resolution achieved by ANTARES is remarkable.”

Researchers identify flaws in the welding process

Within the joint, Di Luozzo and his colleagues identify two areas: they distinguish where all solidification phases are completed and where they are not. In case of incomplete solidification, the scientists find borides in addition to ferrite. This is an indicator of weak points in the joint: the TLPB process did not succeed perfectly at these points and the joint is defective.

Using neutron tomography, the scientists were able to reconstruct the size, quantity and exact location of these weak points in three-dimensional form. Here they still have to improve the welding process in order to obtain a perfect seam.

Non-destructive testing thanks to neutrons

In their experiment, the scientists showed that neutrons are suitable for making borides visible on welding seams. This helps to assess the quality of TLPB welded joints. “The borides at the joint have an extremely negative influence on its mechanical properties,” explains Di Luozzo. In the worst case, this means that the weld is brittle and breaks, and the joined components no longer hold together.

In theory, the TLPB process enables very good mechanical properties. “It is possible for joined materials to achieve properties comparable to those of the base material,” emphasizes Di Luozzo. The product is therefore as strong as if it were made in one piece. That’s why the process is so important: the neutrons can detect defective spots in the welded end product – and in the case of an aircraft engine, this is vital for passengers’ survival.

Originalpublikation:

Di Luozzo, N., Schulz, M. & Fontana, M. Imaging of boron distribution in steel with neutron radiography and tomography. J Mater Sci 55, 7927–7937 (2020). DOI: 10.1007/s10853-020-04556-z

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: