MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

24.08.2017

Hot tests with neutrons

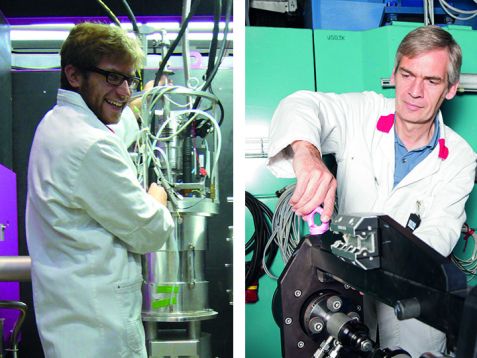

Lukas Karge (left) with the in-situ high temperature furnace at the small angle facility SANS-1 und Dr. habil. Ralph Gilles with the tensile rig for the superalloy at the instrument Stress-Spec. © privat / Sebastian Mast

The efficiency of gas turbines is close to the limit. The state-of-the-art nickel base alloys would not tolerate higher temperatures. Therefore, scientists are looking for an alternative superalloy for the turbine material. Lukas Karge studied a hot candidate for his PhD thesis with Dr. habil. Ralph Gilles at the MLZ.

The new alloy you have studied contains cobalt and rhenium. Why is it more heat-resistant and more stable?

Lukas Karge: Cobalt can withstand high forces, is known in turbine construction and would be a favorable basic material, but can only be used in the medium temperature range. Although rhenium is very expensive, it can withstand higher temperatures. With 3182 °C it has the third-highest melting point of all chemical elements. In contrast, nickel melts already at 1453 °C.

Other components of the new alloy are tantalum carbides and chromium. What characteristics do they have?

Lukas Karge: Chromium protects the material against corrosion or oxidation and tantalum carbides increase the strength. In a simplified manner, such an alloy consists of a matrix in which fine nanoscale precipitates, here the tantalum carbides, are incorporated for stabilization.

Ralph Gilles: Altogether there are eight different elements in it, now the exact mixture and their distribution are extremely important.

What are the advantages of neutrons in the investigation of the alloy?

Ralph Gilles: In the past, material scientists have characterized the alloys mainly under the microscope, only before and after heat treatment at high temperatures, never during heat treatment. The eight elements form different phases and these are difficult to distinguish in the microscope. With neutrons, we can see into the material during the heating and the load or compression tests and determine exactly what happens in the microstructure with which phase.

Lukas Karge: With X-rays only the surface of the material can be examined.

Did the developers at the TU Braunschweig already use measuring results with neutrons to improve the alloy?

Lukas Karge: Yes, in the second batch we received changes, so the material was much more heat- and load resistant. For example, the material has to be previously specially heat-treated so that the elements are first homogeneously distributed and then form the correct phases. I could tell the material developers in Braunschweig exactly how long and at which temperature this heat treatment has to be conducted, so that the distribution is optimal. With neutrons, I could observe the size, shape, and distance of the stabilizing precipitates during the heating phase.

What happens to the alloy when it gets too hot?

Lukas Karge: At very high temperatures above 1300° C, the microstructure becomes unstable, the material becomes brittle. This can in the worst case lead to cracks, which would be fatal in a gas turbine. I wanted to see in my measurements whether this change in the microstructure can be prevented. The tantalum plays an important role, especially, how it is distributed in the microstructure of the alloy.

Up to what temperatures does the alloy hold?

Lukas Karge: It is long-term stable up to 1200 °C.

Ralph Gilles: On the other hand, nickel-base alloys can only be used up to 1100 °C.

What does the temperature increase of 100 °C mean for a gas turbine?

Ralph Gilles: The combustion is cleaner, so less CO2 and NoX is generated and of course we have a higher efficiency of the turbine by up to few percent.

You conducted many measurements on various instruments at the Heinz Maier-Leibnitz Zentrum.

Lukas Karge: Yes, I measured at the SANS-1 small-angle instrument, the Stress-Spec and SPODI diffractometers, and the prompt gamma activation analysis (PGAA) as well as the radiography facility ANTARES. But I was also at the Institute Laue-Langevin in Grenoble, the Paul-Scherrer Institute in Switzerland and the Helmholtz Zentrum Berlin. Besides neutrons, I also used the X-ray diffractometer in the MLZ Materials Science laboratory to characterize the materials in advance. So I could formulate my measuring time proposals better, because I realized what I wanted to measure exactly.

How does a mathematician get the idea to do a PhD using neutrons?

Lukas Karge: I have already worked as a student at FRM II and have already done my master thesis in combination with neutrons and image processing. I was always interested in the application, but also in the theoretical approach and data processing.

Most other materials scientists are rushing into the nickel base alloys and want to improve them. Does cobalt-rhenium have a chance?

Lukas Karge: At the moment, we are the only team involved in the Co-Re system alongside our partners from Braunschweig, Prague and Siegen. Rhenium is on the one hand very expensive and on the other hand the composition is very difficult so that a precise understanding of the kinetics of the phases involved is necessary. Otherwise, the material cannot meet the required high-temperature properties.

Ralph Gilles: The nickel base alloys dominate because they have simply proved their worth. But they are just before the melting point. You cannot get any further. For a long time, there have been no major steps in the development of turbines, cobalt rhenium is a very hot candidate and also contributes to the higher mechanical strength in the current mixture. But it will take at least 15 years to be applied. And there are other ideas for the use of the alloy, e.g. for materials in rocket engines.

The project “Research on precipitation hardening by tantalum carbides in Co-Re base alloys” was funded by the German Research Foundation from 2013 to 2017 under the grant numbers: GI 242 / 4-1 and RO 2045 / 31-1

Four selected publications of the cobalt-rhenium project:

L. Karge, R. Gilles, D. Mukherji, P. Strunz, P. Beran, M. Hofmann, J. Gavilano, U. Keiderling, O. Dolotko, A. Kriele, A. Neubert, J. Rösler, W. Petry, The influence of C/Ta ratio on TaC precipitates in Co-Re base alloys investigated by small-angle neutron scattering. Acta Materialia 132, 354-366 (2017).

R Gilles, D. Mukherji, L. Karge, P. Strunz, P. Beran, B. Barbier, A. Kriele, M. Hofmann, H. Eckerlebe, J. Rösler, Stability of TaC precipitates in a Co–Re-based alloy being developed for ultra-high-temperature applications. Journal of Applied Crystallography 49, 1253–1265 (2016).

P. Beran, D. Mukherji, P. Strunz, R. Gilles, M. Hofmann, L. Karge, O. Dolotko, J. Rösler, Effect of composition on the matrix transformation of the Co-Re-Cr-Ta-C alloys. Metals and Materials International 22(4) 562-571 (2016).

D. Mukherji, R. Gilles, L. Karge, P. Strunz, P. Beran, H. Eckerlebe, A. Stark, L. Szentmiklosi, Z. Macsik, G. Schumacher, I. Zizak, M. Hofmann, M. Hoelzel, J. Rösler, Neutron and synchrotron probes in the development of Co-Re-based alloys for next generation gas turbines with an emphasis on the influence of boron additives. Journal of Applied Crystallography 47, 1417-1430 (2014).

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: