MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

02.04.2020

Embossing instead of cutting

How electric motors can run even more efficiently

PhD student Tobias Neuwirth inserts the sample at the radiography facility ANTARES at MLZ. © Andreas Heddergott / FRM II, TU München

One million electric cars are planned to roll on Germany’s roads. Although the efficiency of an electric motor is more than twice as high than that of an internal combustion engine, a higher efficiency could save a lot of energy due to the large number of vehicles. Using a new measurement technique, neutrons help to make engines even more efficient.

In the case of electric motors, it is particularly important to direct the resulting magnetic fields in the motor to the correct position. Manufacturers usually use electrical steel into which they cut holes. These holes are obstacles for the magnetic field and so its distribution can be controlled. However, this reduces the stability and thus also the maximum speed at which the motor can rotate.

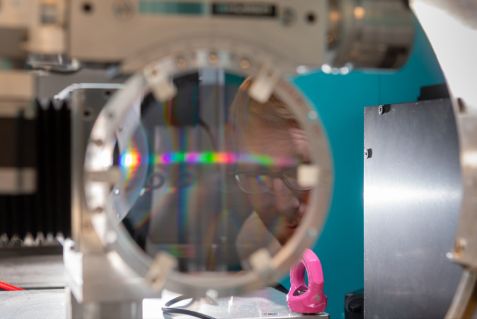

Close-up of the sample with light spectrum, while instrument scientist Dr. Michael is reflected in a part of the interferometer. © Andreas Heddergott / FRM II, TU München

The solution to this problem could be embossing. The embossed regions are just as much an obstacle to the magnetic field as holes. However, they do not reduce stability. With their neutron measurements, the scientists were able to compare different punches for embossing and identify the most effective one.

At the ANTARES instrument of the MLZ, researchers have the ideal environment to study electric motors, since instrument scientists recently installed their improved neutron grating interferometer (nGI). “Nowhere else can you examine such large samples so precisely,” says instrument scientist Dr. Michael Schulz from the MLZ. In cooperation with other institutes (Chair of Forming Technology and Foundry of the TUM and institute for electrical machines of the RWTH Aachen University) they can conduct research on a new production technology for electric motors.

“Neutron grating interferometry is the only technique by which we can determine spatially-resolved magnetic properties of the entire sample. Other techniques can either only examine the surface or only make statements about the whole sample. But that is simply not enough to understand the material,” says Tobias Neuwirth, a PhD student at the Technical University of Munich, who examined the electrical steel and built the new interferometer.

The principle of neutron grating interferometry is very similar to classical imaging methods and takes advantage of the wave properties of the neutrons. However, while common X-ray imaging for example at a doctor only uses the contrast caused by the different levels of absorption, the nGI goes one step further: It also considers the scattering of neutrons and the shift of the neutron waves. With these additional analytical possibilities, the researchers can study magnetic properties in a spatially-resolved manner. The new interferometer has the highest sensitivity in the world, which allows high-precision measurements even with the smallest changes in magnetic properties.

Original publications:

B. Schauerte, N. Leuning, S. Vogt, I. Moll, H. Weiss, T. Neuwirth, M. Schulz, W. Volk, K. Hameyer.

The influence of residual stress on flux-barriers of non-oriented electrical steel. Journal of Magnetism and Magnetic Materials, Volume 504, 15 June 2020, 166659. DOI: 10.1016/j.jmmm.2020.166659

T. Neuwirth, A. Backs, A. Gustschin, S. Vogt, F. Pfeiffer, P. Böni, M. Schulz.

A high visibility Talbot-Lau neutron grating interferometer to investigate stress-induced magnetic degradation in electrical steel. Scientific Reports 10, 1764 (2020). DOI: 10.1038/s41598-020-58504-7

S. Vogt, T. Neuwirth, B. Schauerte, H. Weiss, P. Falger, A. Gutschin, M. Schulz, K. Hameyer, W. Volk.

Extent of embossing-related residual stress on the magnetic properties evaluated using neutron grating interferometry and single sheet test. Prod. Eng. Res. Devel. 13, 211–217 (2019). DOI: 10.1007/s11740-018-0863-7

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: