MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

26.1.2018

Another Gyro Gearloose at the MLZ

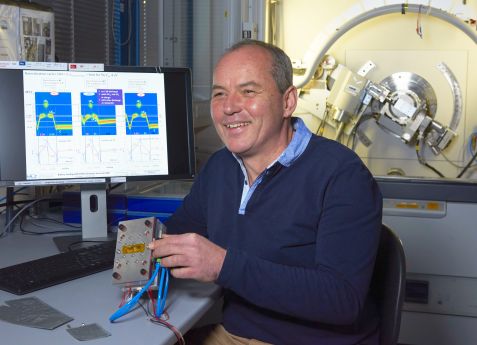

Armin Kriele with the add-on for the X-ray diffractometer (in the background), which he developed and which makes measurements on pouch cells considerably more precise. Such a measurement can be seen on the screen, some pouch cells are in the foreground on the table. © w. Schürmann / TUM

Armin Kriele from the Helmholtz Center Geesthacht has something in common with the famous inventor of Walt Disney: Both make inventions for the joy of working. Kriele is responsible for the Materials Science Laboratory at the Heinz Maier-Leibnitz Center and has a lot to do with batteries of all kinds. For their detailed analysis, he has now made an invention and applied for a patent.

Lithium-ion batteries with their various designs are practically ubiquitous today. However, their performance requirements are increasing because they are being used more and more frequently, for example, as storage media or for electromobility. Not all is known about the processes inside, especially during fast charging and discharging and at low temperatures, so scientists are relying on fast measuring methods. Armin Kriele has been thinking about how the so-called pouch cells can be tested non-destructively during operation at a wide range of operating temperatures.

Pouch cells consist of a foil bag coated with aluminum, in which all the necessary components of a battery such as anode, cathode, separator and electrolyte are contained. Very useful for many applications is that these pouch cells are only up to 5 millimeters thick and usually flexible. Naturally, the scientists at the MLZ intensively investigate the processes inside with neutrons, however, much faster and sufficient for many questions is the in situ X-ray scattering, in which the cells can be irradiated without opening. The X-ray penetrates into the battery sample and is thereby diffracted at the crystal or quasicrystal structures. By measuring the scattering angles and the intensities of the diffracted beams, the positions of the atoms in the crystal as well as their chemical bonds, dislocations and other information of all the active materials within the battery are simultaneously determined as a function of the state of charge. For example, the migration of lithium ions into the anode during charging (intercalation) and back to the cathode during discharge (deintercalation) can be closely monitored.

Improved analysis of batteries

However, what happens when charging and discharging a battery at very low or very high temperatures? Do the same charging speeds apply here as at room temperature? Everyone has the experience in everyday life that the performance and life of a battery in freezing temperatures drops significantly and defects in the battery at high temperatures occur quickly. A circumstance that is particularly important for electric mobility, where the batteries should function optimally both in summer and in winter. Armin Kriele has now developed a combined heating and cooling device, which allows running simultaneously three processes during operation: temperature control, charging and discharging and X-ray measurement.

Low temperatures were a particular challenge. It is well known that water condenses on cold surfaces from the ambient air. If the surface is very cold, it forms a layer of ice. This had to be avoided necessarily in the tempering device, since each additional layer would significantly falsify the measurement. Armin Kriele has developed this through a two-chamber concept that is hermetically sealed and purged with inert gas.

Here, the two temperature control chambers work together: The first releases heat from the battery cell by means of Peltier elements to the second outer housing, which in turn dissipates this heat completely via fans or water cooling. Of course, this type of derivative can also be used in reverse order, e.g. to conduct heat from the outside into the battery and thus to simulate the summer mode. Batteries can be tested at temperatures between -40 ºC and +80 ºC. The device is small and can be connected to all commercially available X-ray diffractometers, which use industry and research for material analysis; but it is also suitable for synchrotron and neutron measurements. For this, Armin Kriele has also designed a coupled alignment device that allows the sample to be moved three-dimensionally: “This not only allows to examine pouch cells accurately and over a wide temperature range, but actually all flat samples, even if they are uneven. Then simply level out the uneven surfaces with heat conducting films.”

The Patent Office is expected to decide on the application in May 2018. Then Kriele can decide what the next step should be. He already has an assessment: “There is a market for it, because these X-ray diffractometers are in the thousands in industry and research. And as long as electromobility is such an intense field of research, my invention will be extremely useful.”

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: