MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media:

MLZ (eng)

Lichtenbergstr.1

85748 Garching

24.11.2023

Closer to the dream of nuclear fusion with positrons

Nuclear fusion could help solve the energy problem in the future. However, there are still numerous challenges to overcome before then. Among other things, the inner walls of the fusion reactor must be able to withstand extreme conditions. Positrons help researchers to study these materials.

The materials in the walls of a fusion reactor have to withstand high levels of radiation and heat: Here is a view into the plasma vessel of the ASDEX Upgrade fusion facility. © MPI für Plasmaphysik / Jan Hosan

How can an artificial sun be shielded?

Candidates for the reactor wall material include tungsten and Eurofer 97, a steel alloy made of iron, molybdenum, and other elements. The steel is exposed to radiation in the fusion reactor, which detaches individual atoms from their lattice position in the metal. Individual helium nuclei can initially be deposited in these tiny gaps, gradually forming larger and larger pores. The mechanical stability deteriorates as a result of this pore formation.

Getting to the heart of steel with positrons

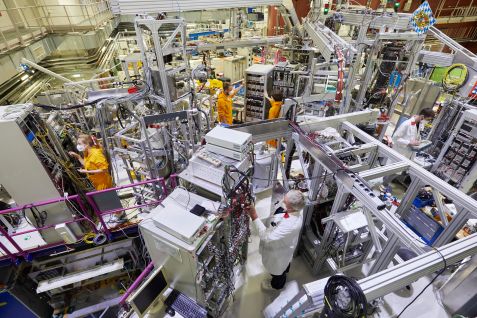

Prof. Dr. Christoph Hugenschmidt and his team generated a positron beam at NEPOMUC at the Heinz Maier-Leibnitz Zentrum (MLZ) to understand how these effects occur. The researchers are taking advantage of positrons living longer when they are in atomic vacancies or tiny pores. This is because the positrons have fewer electrons to collide with as their antiparticles.

In addition, the research team can use the positron annihilation spectrum to determine the speed of the electrons with which the positrons annihilate. The researchers can draw conclusions about the size and type of defects from this data.

At NEPOMUC, the world's most potent positron source, scientists have investigated the materials for fusion reactors. © Bernhard Ludewig, FRM II / TUM

“The positron source at the MLZ generates a beam 100 times stronger than conventional sources. As a result, it penetrates much deeper into the material and allows conclusions to be drawn about the structure down to a depth of up to one micrometer,” says Prof. Dr. Vladimir Slugen from the Slovak University of Technology in Bratislava, who was involved in two of the three investigations.

Improved performance thanks to impurities

Slugen and his team improved the steel’s radiation resistance by adding other elements, such as tungsten and tantalum. They were able to further enhance by adding yttrium oxide to the steel. This forms small particles in the material, whereby helium can accumulate at the interfaces. This prevents the formation of larger pores, which weaken the alloy.

Helium alone does not cause damage

As part of further measurements on tungsten samples, Hugenschmidt, in collaboration with researchers from the Max Planck Institute for Plasma Physics, found that helium is not able to significantly damage the metal at lower temperatures, even if the material used has already suffered minor damage.

These findings are important for developing optimal wall materials for fusion reactors and ensuring their safe operation.

Original publications:

Vladimir Slugen, Jana Simeg Veternikova, Jarmila Degmova, Stanislav Sojak, Martin Petriska, Pavol Noga, and Vladimir Krsjak

Positron annihilation studies of Eurofer97/ODS steels after helium ion implantation

Nuclear Materials and Energy 34 (2023) 101369

10.1016/j.nme.2023.101369

Vladimir Krsjak, Tielong Shen, Jarmila Degmov, Stanislav Sojak, Erik Korpas, Pavol Noga, Werner Egger, Bingsheng Li, Vladimir Slugen, and Frank A. Garner

On the helium bubble swelling in nano-oxide dispersion-strengthened steels

Journal of Materials Science & Technology 105 (2022) 172–181

10.1016/j.jmst.2021.08.004

A. Kärcher, T. Schwarz-Selinger, V.V. Burwitz, L. Mathes, C. Hugenschmidt, and W. Jacob

The influence of displacement damage on helium uptake and retention in tungsten

Nuclear Materials and Energy 34 (2023) 101370

10.1016/j.nme.2023.101370

More information:

The mentioned projects received financial support from the Euratom research and training program 2019-2020 (grant agreement No 945041 SafeG and No-101061201 DELISA-LTO) and The Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences (grant numbers VEGA 1/0382/20 and VEGA 1/0395/20) and the European Regional Development Fund (projects No. ITMS2014+: 313011BUH7 and ITMS2014+: 313011W085) and the Slovak Research and Development Agency under the project APVV-20-0010 and the German Research Foundation (DFG, German Research Foundation, Germany) – EXC-2035/1- 429845086.

In addition to researchers from the Technical University of Munich, the Heinz Maier-Leibnitz Zentrum, and the Max Planck Institute for Plasma Physics, scientists from the Slovak University of Technology in Bratislava, the Chinese Academy of Sciences, the Universität der Bundeswehr München, the Southwest University of Science and Technology, Texas A&M University and Radiation Effects Consulting LLC were also involved.

Related News

-

15.04.2021

Using antimatter to combat plastic waste

-

15.12.2018

Trapped antimatter

MLZ is a cooperation between:

> Technische Universität München

> Technische Universität München > Helmholtz-Zentrum Hereon

> Helmholtz-Zentrum Hereon

> Forschungszentrum Jülich

> Forschungszentrum Jülich

MLZ is a member of:

> LENS

> LENS > ERF-AISBL

> ERF-AISBL

MLZ on social media: